March 6, 2019

Scupper 94

Wednesday

After unclamping the laminated electric motor platform, I cleaned up some epoxy squeezeout from the edges, then test-fit the platform in the engine room once more, double-checking it for level and against the alignment marks I’d put on the hull and also in relation to the shaft string, which I set up again for a final check.

I used the platform itself to create a pattern for the fiberglass that I’d use to secure it to the hull, and with that done I coated the bottom side of the platform with epoxy, then installed the platform in a bed of thickened epoxy adhesive along the edges and atop the vertical brace in the bilge beneath. I installed a lavish fillet along the edges where the platform met the hull, and used excess epoxy to coat the top of the platform and the adjacent hull areas as well, before cutting out four layers of 1708 fiberglass and installing them with epoxy resin.

Next, I lightly sanded the new holding tank shelf in the head, completing work there for the moment.

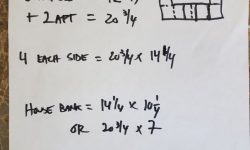

The epoxy primer in the other parts of the cabin had now cured enough so I could continue lightly sanding those areas as required, then cleaned up the spaces, particularly the forward cabin, where I planned to do some painting later in the day. I had to depart the shop for a couple hours, but with a little time on hand before then I started some rough layout for the planned battery bank for the electric propulsion system, which would consist of eight six-volt batteries to make up the 48-volt bank required. In addition, there’d be two separate batteries to make up the 12-volt system for the ship’s basic services (lighting, etc), but that pair didn’t pose any installation issues.

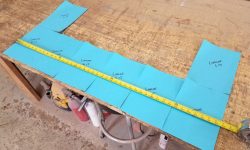

With a series of paper cutouts I made to the overall size of the chosen batteries, I set up and measured a few layout alternatives so I could better measure the spaces in the engine room and, in concert with the owner, determine the desired placement for the batteries, after which I could move forward with constructing whatever was needed for that purpose.

When I returned in the afternoon, I got to work in the forward cabin and painted the chainlocker and insides of the hull on both sides, along with the interior of a small locker at the end of the berth.

I now had all the bronze and other supplies for the four new through hulls required (two cockpit scuppers; galley sink drain; holding tank pumpout), and it seemed a good time to prepare the 3/4″ G-10 backing plates, which I cut out to fit each base. I’d be continuing this installation in the near future.

To round out the day, I spent a little time on some layout for the forward cabin door trim. The original doors simply slid in a milled groove in the wood, but I thought I could improve upon that with some UHMW plastic inserts, which would make the operation slipperier. First, I’d have to mill a large dado to accept the 3/4″ square strips of UHMW, and then mill the door groove in that. For the long bottom piece, this would require a cut that started well in from the end of the trim, and ended before the other end, since this new trim extended all the way across the bottom of the bulkhead, and this required some additional layout steps that I worked on now, though I chose not to do the millwork this late in the day.

Total time billed on this job today: 6 hours

0600 Weather observation: 0°, clear. Forecast for the day: Sunny, 23°