June 11, 2019

Scupper 155

Tuesday

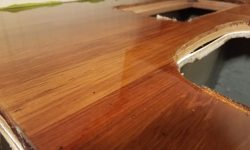

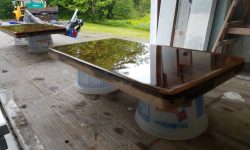

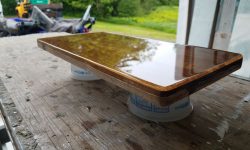

With the countertop cured sufficiently (though full cure would take a few days), I removed all the duct tape and masking tape from the countertop and hatches. Though the epoxy coating was below the level of the masking tape along the edges of the countertop, the application process had spread some epoxy up and over the tape in several areas, which only meant it took some fine work to remove all the tape. Without a full cure, I was wary of doing any damage to the fresh and highly glossy surface, so worked with extra care.

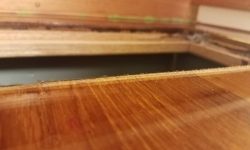

Removing the duct tape that had formed the dams revealed an unforeseen small problem: the epoxy, though surface tension, had slightly climbed the duct tape dams at the countertop openings and around the hatch perimeters, leaving a raised edge when the tape was removed.

This wasn’t a problem on the stove and sink openings, where the edges would be covered by the installation flanges, but for the countertop storage lockers and lids, where the edges were the finished surface, I’d have to remove the raised part carefully. I found I could use a sharp knife to pare away some of the excess now, but decided to leave the final resolution till later when I’d had some time to consider options.

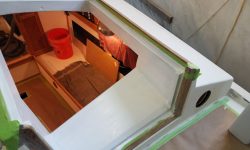

Meanwhile, I masked off the areas to be primed and painted around the companionway, then, after final preparations, applied a coat of white primer. At the same time, I primed the interior port trim rings.

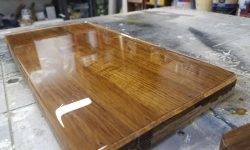

Later, working with the two loose hatches on the bench, I sanded the edges to remove the unwanted raised epoxy, staying away from the glossy field by keeping the sandpaper angled just to remove the edge. I worked through several grits in this process, ending at 220, with a smooth and clean edge. To finish off the edge, I mixed a small batch of the tabletop epoxy and applied it just to the sanded edges with a brush, which worked quite well. I’d do the same treatment to the countertop openings a little later.

Total time billed on this job today: 4 hours

0600 Weather Observation: 60°, clouds and showers. Forecast for the day: Showers, 65°