November 20, 2019

Scupper 187

Wednesday

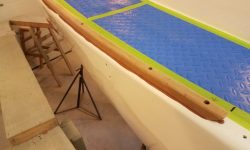

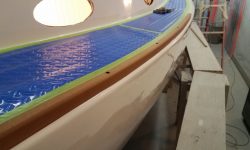

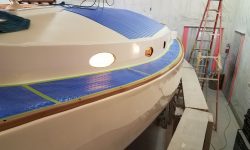

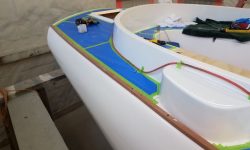

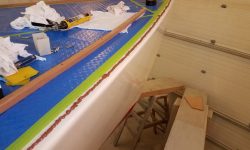

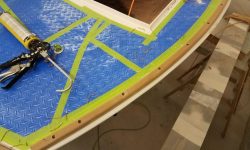

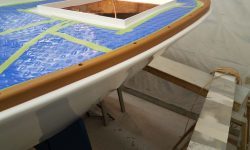

With everything ready to go, it was a relatively simple matter to permanently install the port toerail. For each section, I applied a heavy bead of sealant to the deck, then installed the toerail with the screws I’d used during the dry fit. Once each section was secured, I cleaned up the excess sealant, then moved on to the next section.

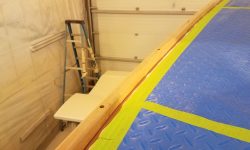

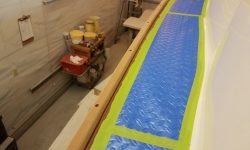

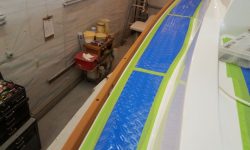

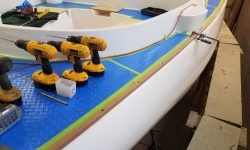

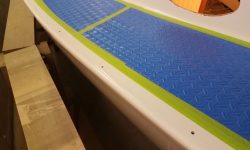

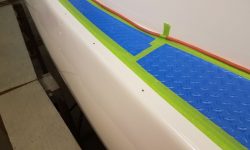

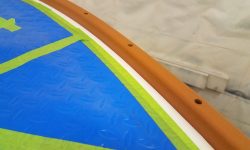

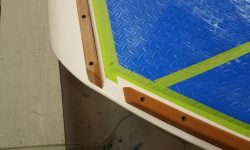

I moved my operation to the starboard side, and, starting at the stem, repeated the dry-fit process with the starboard toerail, working aft to the transom. As before, I dry-fit the final section at the transom and let it run wild so I could mark and then trim the final length and shape at the end. Before removing the rails, I measured and marked for the three drains in the rail, using the measurements I’d determined from the port side to do so.

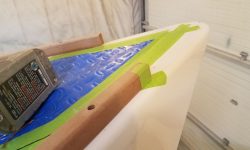

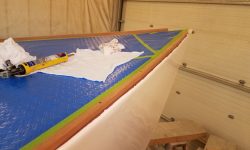

After removing the starboard rail sections, I milled countersinks at each fastener location, then cleaned and prepared the deck surface for the final installation. Down on the bench, I marked and cut out the drain openings, and cleaned all the rail sections.

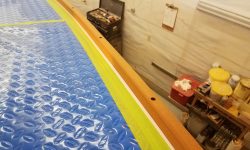

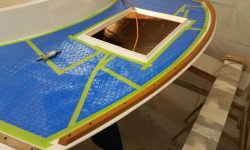

Now I repeated the final installation process with the starboard toerail.

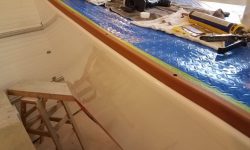

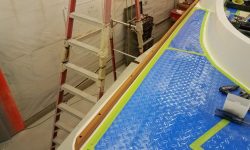

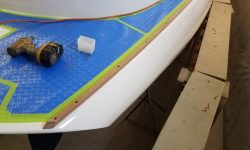

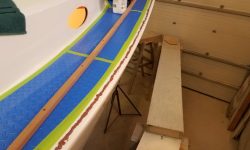

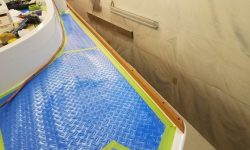

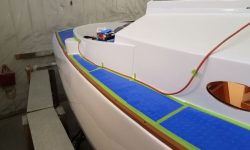

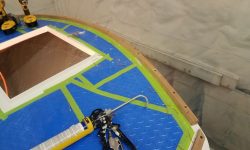

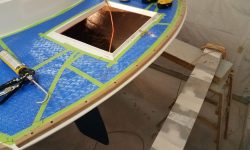

Normally (i.e. using wood), the compound curvature at the transom would have been too extreme to bend a single piece of toerail into place, but in this instance, the flexible plastic wood material was up to the challenge, which streamlined the construction of the taffrail. I cut a length of the previously-prepared toerail stock to rough length to fit between the ends of the toerails, then, starting at centerline, bent and secured the taffrail blank in place, following my layout line and working towards the transom corners in each direction. Once the taffrail was secured, I determined the width of the scupper opening at each corner, between the toerails and the new taffrail, and marked layout lines for the taffrail cuts; these lines also dictated the position of the final screws on the taffrail, which I placed the same distance from the eventual cutline as those on the adjacent toerails.

Removing the taffrail to the bench, I trimmed the ends according to my lines, cutting a similar angled profile as on the toerail ends, then installed the taffrail permanently in a bed of sealant.

Total time billed on this job today: 8.25 hours

0600 Weather Observation: 34°, cloudy. Forecast for the day: Cloudy, slight chance of rain or snow, 38°