February 26, 2020

Scupper 250

Wednesday

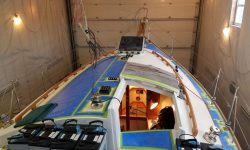

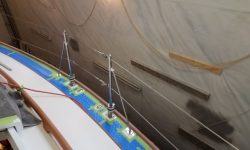

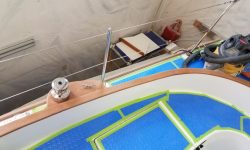

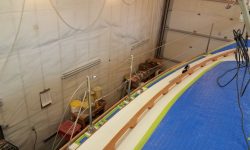

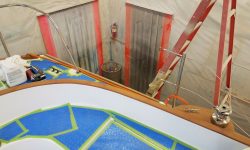

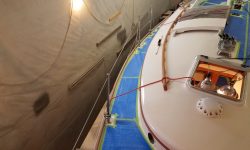

Mike from the rigging company was on hand during the morning to finish up the final rigging work: installing the new lifelines, reefing lines in the boom, and the Tides Marine mainsail track on the mast. For now, I had Mike leave the port after set of lifelines detached from the pulpit, since this was where I boarded the boat at the moment.

I had another commitment away from the shop during part of the morning, but I spent all of my day working on the engine room batteries, beginning by installing the last ratchet straps and hold-down strap brackets for the remaining three sets of batteries (two each). As before, I bolted the straps in place through the bulkhead in all cases. The chore was straightforward, and access to this side of the engine room was better than the far outboard side, but it was still a time-consuming process to get all the straps and brackets in place.

With all the preparatory work done, and the battery box top hold-down straps secured to all three remaining boxes, I managed to get two of the three remaining pairs of batteries in place during the afternoon, starting with the starboard outboard set (on the original starboard shelf in the engine room), then the port set on the centerline platform forward of the engine. This seemed so simple, but the battery weights, tight quarters, and other logistics meant that each installation required lowering a pair of the batteries from the cockpit to the cabin; setting up and modifying as necessary the 2×4 sliding platforms; placing the batteries in their boxes; sliding the boxes into position (fortunately much easier for these sets than it had been for the first set on the port side earlier); and securing each box with the ratchet strap, hold-down strap, and the battery box top strap.

One pair of batteries remained, and I was excited about completing the installations, but the day was growing short and I thought it’d be better for me to wait to schlep the final pair of batteries from the cockpit into the cabin and then into the engine room, as I was feeling the day’s efforts and needed to save myself, so after modifying the ramp through the head for the final pair of batteries, which would go directly inside the engine room door, I called it quits for now.

Total time billed on this job today: 5.75 hours

0600 Weather Observation: 33°, cloudy. Forecast for the day: Cloudy, 42°