June 4, 2019

Scupper 150

Tuesday

With base coats complete on both sides of the forward cabin doors, I switched now to the rubbed-effect satin finish for the next coat on the main cabin side of the doors.

Working in the cabin, I lightly sanded the first coat of varnish on the companionway door trim, then cleaned up to prepare it for varnish later in the day.

In the meantime, I turned to the galley countertop. Working with an anecdotal assumption, formed over 52 years of direct experience, that ambient temperatures in the area would someday during the coming months eventually rise back into the mid- or upper 70s or higher (an elusive benchmark thus far this season), making it feasible for me to pour the self-leveling epoxy coating for the countertop surface, I wanted to get some final preparatory steps completed now so that when the time came, there’d be nothing standing in the way of the temperature window and completion of this crucial part of the interior. Sure, I could raise the heat in the shop to this level if needed (and I would if I had to), but I thought it seemed likely that Mother Nature could take care of the temperature if I maintained patience. It wasn’t going to happen this week, but I’d be ready when it did.

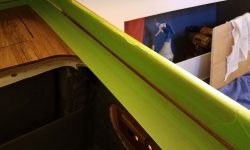

Whether necessary or not, I wanted to seal around the edges of the countertop where it met the bulkheads, ceiling, and trim to ensure that the top surface would contain all the liquid epoxy when I installed it and to prevent any chance of leakage down some small gaps or cracks. I’d never worked with the pourable epoxy coating before, and wasn’t about to take a chance of ruining an adjacent surface or compartment (not to mention the countertop) with seepage. I removed the paper covering I’d had in place over the countertop for protection, then with a spacer masked off clean lines 1/8″ on either side of the seams along the edges on all sides. I added another width of tape for extra protection.

Next, I applied a bead of brown sealant, pressing it tightly into the corners and gaps with a finger and removing most of the excess in the process.

A little later, once the sealant had tacked up, I removed the masking tape to leave clean lines on both sides. I hoped and planned that this bead would provide the necessary damming at the countertop edges to prevent any epoxy loss through the gaps.

Afterwards, I finished up a small lingering task in the head, where I installed a pair of door catches on the engine room door to hold it securely closed.

This took care of my interior plans for the day, so I finished up with a second coat of varnish on all the companionway trim areas.

Total time billed on this job today: 5.5 hours

0600 Weather Observation: 45°, clear. Forecast for the day: Sunny, 68°