November 25, 2019

Scupper 190

Monday

After some administration and a planning session early in the morning, I had to leave the shop on other business for part of the day, but in the afternoon I got back to work on the deck trim, starting with the handrails. With the sealant cured, it was a relatively simple process now to remove the excess and the masking tape. I had hoped to bung the screw holes, but ran out of time later in the day.

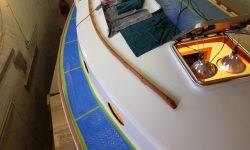

I removed the dry-fit eyebrow and finalized preparations, including milling my usual little countersinks at each fastener location, then cleaning up the bonding surfaces. I cut the two after pieces of eyebrow trim to the proper length where I’d marked them, and prepared all three pieces for final installation.

I’d thought about using tape to mark the top edge of the eyebrow position before I’d removed it, but decided against it, thinking it wasn’t necessary. This was a decision I quickly regretted, as installing the eyebrow in a good bed of sealant turned out to be fussier than I’d anticipated, mainly because it was challenging to find the screw holes in the boat beneath the sealant bead, particularly the first few. I got it done, but it was messier and more frustrating than I’d anticipated, particularly with the first piece that rounded the forward part of the cabin trunk, but even the shorter side pieces, which I could install at eye level from the staging, proved to be more time-consuming than I’d expected.

Because I wanted to ensure a solid and consistent bead of sealant at the top edge of the trim once installed, I’d used a fairly heavy amount beneath, which required substantial cleanup but ultimately achieved the goal.

With the eyebrow complete, I moved on to the winch islands, each of which required six screws (placed to avoid the anticipated winch base bolt pattern) that I drilled and tapped into the fiberglass beneath before installing the trim in a bead of sealant and bunging the screw holes.

Total time billed on this job today: 5.25 hours

0600 Weather Observation: 32°, clear. Forecast for the day: Mostly sunny, 45°