February 4, 2020

Scupper 234

Tuesday

First thing, I finished up the gate braces’ installation, a straightforward task.

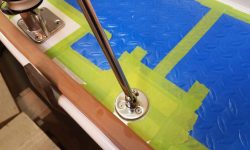

I’d already marked the fastener locations for the inner forestay attachment point on the bowsprit, so now I double-checked the marks, then drilled the holes slightly oversized for the 5/16″ bolts that would secure the hardware. Then, after masking off the bare teak around the base, I installed the inner forestay with new fasteners and sealant.

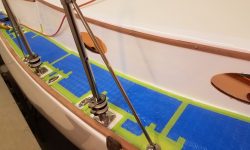

At the cockpit and winch islands, I laid out the positions for the new jib sheet winches, ensuring ample clearance between the winch handles and the nearby stanchions before marking the winch island for the fastener locations. Since the self-tailing strippers on this particular model winch were fixed in one position only, I aligned the winches according to the desired position of the strippers on each side of the cockpit.

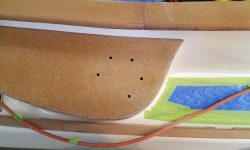

Afterwards, I used a long bit to drill through the winch islands for all the 1/4″ fastener locations, then used the bit, inserted so it was just penetrating the underside, to measure the depth of the holes at the deepest points, which I marked with tape above. Because the underlying (original) winch islands were an angled molding, the underside of the islands was also angled, so the fastener length required varied from inboard to outboard accordingly. The outer depth was about 6″, and I was able to find and order 7″ long flat head fasteners to suit the bill; the shorter versions for the inner locations were easier to find.

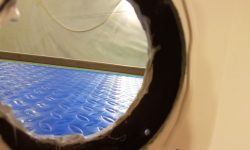

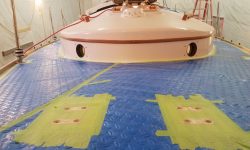

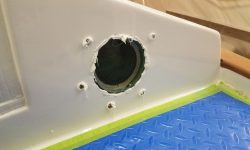

After some final prep and fastener/tool collection, I turned to the bronze ports: three small round ones, and the large one over the galley. Beginning in the forward cabin, I dry-fit the ports to check their fits in the existing openings. As expected, the clearance was extremely tight, and I needed to assess how best to seal the ports during installation. These ports fit from the inside out, and were to be secured with four bolts from the outside. All the fastener holes were in place, but I reamed them out a bit to ensure easy passage of the new fasteners.

For installation, I applied sealant around the inside of the round opening, so that the port spigot would push through it as I installed it from the inside. Though I normally wouldn’t seal the inside mounting flange of a normal (i.e. trim ring) port installation, here I felt that the additional layer of protection was necessary since there was so little space for a guaranteed good seal around the spigot, though it turned out that the sealant appeared to do the job well once I’d installed the ports.

With both ports sealed and installed from the inside, and aligned with the mounting holes, I went on deck and installed the new bronze fasteners with ample sealant around their tops and heads. Then, I secured the ports with nuts and washers within.

I finished up the installations by cutting the excess bolt length and installing the original bronze cap nuts over the exposed fastener ends, then cleaning up the excess sealant on the outside of each port.

I repeated the installation process with the similar round port in the head, though here it was a tight fit into the space from inside.

I finished up the day with the last bronze port installation over the galley. This port was traditional in that it featured a trim ring from outside, so bedding this port was more straightforward.

Total time billed on this job today: 7.25 hours

0600 Weather Observation: 25°, mainly cloudy. Forecast for the day: Partly sunny, slight chance of rain or snow showers after noon, 38°