February 10, 2020

Scupper 238

Monday

With my days for the immediate future slightly truncated at each end as we settled in to new routines with a new puppy at home, I got a somewhat late start with the day’s work.

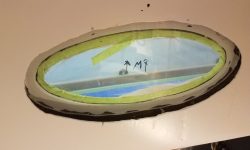

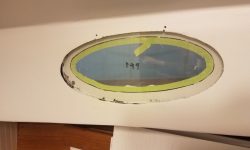

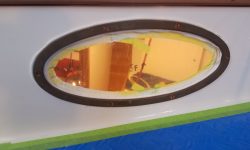

Four of the new deadlights had had the weekend to cure in place, so now I removed the shims from inside, leaving the acrylic lenses firmly in place. I removed the protective plastic film from the inside surfaces.

With the wedges freed up, I could go ahead and install the remaining two lenses on the starboard side, using the same techniques as on the previous four.

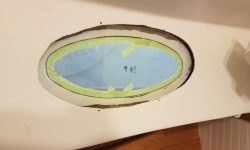

The next step towards completing the installations was to lay out and drill fastener holes for the exterior bronze trim rings. These rings performed no particular structural purpose whatsoever, but finished off the openings from the outside. Since the bolts to secure the rings would also pass through the new lenses, the trim rings would also help secure the plastic, though in this installation that was a secondary benefit.

Not that it probably mattered, but during removal of these deadlights long ago I’d marked each trim ring for its location, and now, using the appropriate ring for each port on the port side, I dry-fit the rings, drilling and tapping for #8 machine screws at the six screw locations. I held the ring temporarily with the two end screws while drilling and tapping the remaining four holes. Afterwards, removing the trim ring, I milled the usual small countersinks in the cabin side.

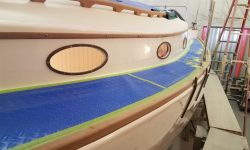

With the three ports on this site thusly prepared, I applied sealant to the perimeter of the openings and installed the trim rings permanently, cleaning up excess sealant afterwards and finishing up my removing the exterior protective plastic film from the lenses.

I repeated the process with the starboard forward port, the last of the original four.

Inside the boat, I installed nuts and washers on the new machine screws, then finished up the installations with the interior trim rings.

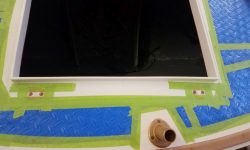

In a couple days, I could repeat the final processes on the two starboard after deadlights, but for the moment I took a few minutes to finish up a couple small jobs from the list, starting with replacing the screws on the anchor windlass circuit breaker, swapping the ones I’d used originally for some black-finished stainless screws that better matched the panel. I also removed the protective paper from the forward hatch–a small thing, but a good sign as it signaled the end of the project was nigh, and there was no longer any reason to hold off.

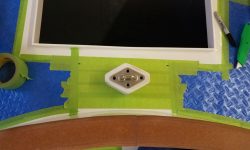

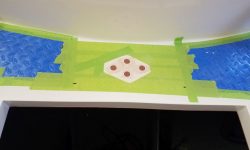

I’d held off installing the cockpit locker hatches and lazarette hatch as long as possible, but now it was time to start thinking about final installations, starting with the new lazarette hatch in the poop deck. I laid out a pair of small yet hefty stainless hinges on the aft side, and pre-installed the hatch side of the hinges with sealant and small bolts before marking the hole locations on the deck and removing the core from around the four screws in the usual way.

Afterwards, I laid out and prepared the fastener locations for the mainsheet padeye and riser, even though the riser was still in primer only and awaiting its final finish. With these holes prepared, along with the hatch holes, I filled all the holes with a thickened epoxy mixture, finishing up the day by spec’ing and ordering some materials I’d need to finish up the battery installations in the coming days.

Total time billed on this job today: 6 hours

0600 Weather Observation: 33°, light rain, 2″ snow overnight. Forecast for the day: Rain showers, then cloudy, 39°