January 31, 2020

Scupper 232

Friday

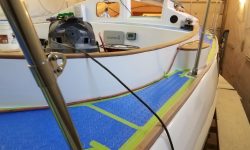

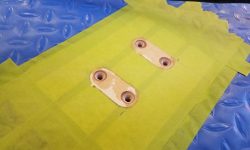

Easing into the day with a simple yet necessary task, I installed the four pulpit brackets that would support the lower lifeline attachments.

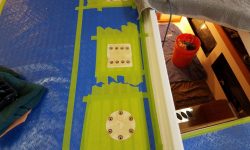

The cabin top was ready for the final installation of the new hardware, so to begin I drilled, tapped, and countersunk all the fastener holes for the winch, rope clutch, and fairlead.

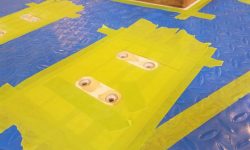

Belowdecks, I marked and cut away the liner in way of the winch and rope clutch, and drilled two 1-1/2″ holes with a hole saw at the fairlead fastener locations. This exposed the underside of the deck proper. For the winch and rope clutch, I prepared backing plates from fiberglass sheeting to fit in the new openings.

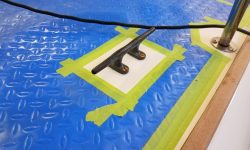

I began the installation with the fairlead, which was furthest forward and the simplest installation overall. I applied sealant and installed two 1/4″ bolts. I discovered that I’d cut away the liner from the wrong hole beneath (there are many old holes in the liner), and had to cut a new opening for the inboard fastener on the fly. These holes accepted large fender washers to secure the fairlead.

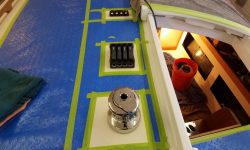

Next, I installed the winch base with sealant and six bolts, using the backing plate and fender washers beneath. There was just enough room so that the backing plate and nuts fit just flush with the existing liner, which was important since the new overhead panels fit closely to the old liner.

The rope clutch admonished the user not to use polysulfide or polyurethane sealant, and since my standard sealant is a light polyurethane, I used butyl tape instead to install the rope clutch with its eight bolts, installing the new backing plate and fender washers beneath.

This completed the hardware installation for the aft-led control lines.

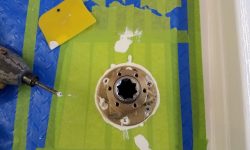

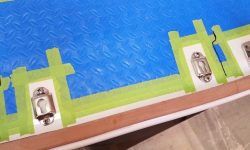

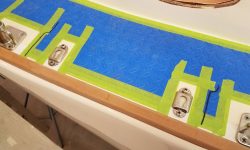

Next, I drilled, tapped, and countersunk all the fastener holes for the stern cleats, ladder brackets, and bow cleats.

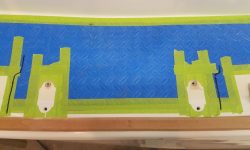

The varnished wooden backing plates for the bow cleats weren’t yet ready for installation, but I could proceed with the stern cleats after making a pair of fiberglass backing plates to fit.

To gain access to the underside of the deck at the ladder mounts, I had to cut away more of the liner to expose the deck. I hated to do this, but there was nothing for it, and these new openings were between the existing openings I’d cut for the lifeline stanchions, so when I built trim to cover the cutouts I could simply plan to do it in one fell swoop.

Because I didn’t want a mess of sealant to ooze into the open space of the bracket mounts required for the top of the ladder, I chose butyl tape to seal the brackets, and bolted them in place with large washers beneath. The ladder fit well on both sides, but I’d have to later trim to length the standoff brackets on the ladder so it would be properly supported by the hull.

With that, and after a bit of boat and shop cleanup, I reached the end of the day’s work.

Total time billed on this job today: 7.25 hours

0600 Weather Observation: 11°, clear. Forecast for the day: Sunny, 39°