February 21, 2020

Scupper 247

Friday

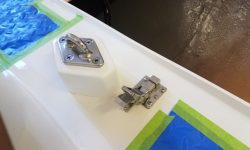

Now that the new paint on the mainsheet riser block had had sufficient cure time, I installed it and the mainsheet padeye, securing them to the holes I’d previously prepared on the deck with long bolts, backing plate, and large washers. I thought this was the final piece of deck hardware to install.

I spent the rest of the morning, and into the afternoon, working on the battery box layout and details in the engine room. Space was tight, and I had to make various minor accommodations for the boxes and their modified tops to fit properly: one box on each of the (original) side shelves port and starboard, and two boxes on the new athwartships shelf I’d built for this purpose along the front edge of the engine room. In my mind, there’d been a lot more room for cleats than it turned out to be in reality, and I had to make some changes to my mental plan, including temporarily removing the large battery cables from the center of the platform to make room for a wide cleat beneath. In any event, at some length and with everything fitting effectively, I made marks on the platforms where the boxes and support cleats needed to be, then sanded away the paint in areas where I’d be bonding the cleats in place with epoxy, cleaning up afterwards.

Then, I re-milled or milled anew from leftover teak the various cleats required.

After final preparations, I glued and (for the notched cleats fitting over the aft edge of the athwartships platform) screwed the cleats in place, using abundant thickened epoxy adhesive.

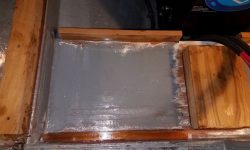

Finishing up the battery work for the moment, I applied some two-part epoxy primer to the fresh epoxy on the house battery cleats and environs, which would allow me to apply the final coat of gray paint over the weekend.

Using up the day, I laid out my tiller-laminating board with some fresh plastic atop, and drew on the shape of the tiller mockup. Then, I milled a stack of teak strips, cutting them to about 3/16″ thick and 2″ wide, which I hoped had a chance of bending to the shape of the tiller blank. I milled a few extras, and used one to try a dry-bend by clamping it directly against the raw tiller blank. Unsurprisingly, the strip failed to make the sharp double-bend at the tiller butt–I’d had hope, but no expectations, that it would. My options might be to use thinner laminations (I had one or two on hand for testing), or to let the bending ability of the strips choose the final shape of that end of the tiller. But in either case, that’d be something to address next time.

Total time billed on this job today: 7 hours

0600 Weather Observation: -12°, clear. Forecast for the day: Sunny, 26°