November 27, 2019

Scupper 192

Wednesday

To start the day, I continued work on the underside of the companionway hatch, which needed a light sanding and then the first of a couple coats of the same semi-gloss white enamel I used throughout the the interior.

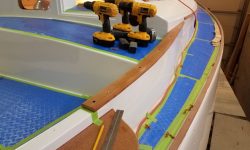

Next, I turned to the starboard coaming, where during the course of the morning I repeated the templating and milling process I’d done to port. Not really expecting it to work, but figuring it was worth a try regardless, I checked to see if the templates from the port side would work if flipped over for the starboard side, but while the forwardmost piece almost worked, the others clearly wouldn’t, owing to slight differences in the original molding, so I made fresh templates for the starboard side.

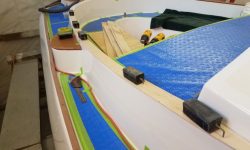

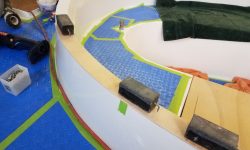

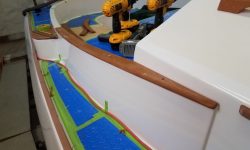

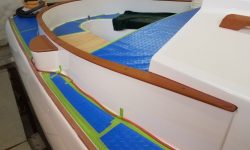

As before, I traced the templates onto the coaming stock and cut out and milled the pieces, taking some extra time now to completely finish the edges before dry-fitting the starboard pieces into place with screws.

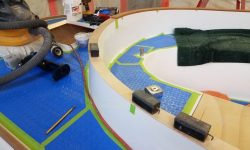

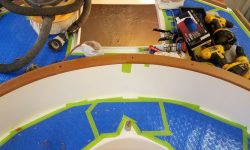

Now I removed all the pieces from both sides, and did all the final prep to the screw holes in the coaming, after which I vacuumed and solvent-washed the surface.

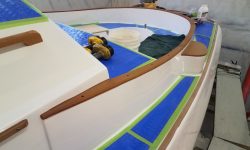

Down on the bench, I finished as necessary the boards from the port side, which still needed a bit of final cleanup at the rounded edges. I discovered a method of dealing with cut,milled, or sanded edges and surfaces on the plastic material that helped return it to its more or less original color: light treatment with heat from a torch. In this photo, the portion to the right has just been lightly heated with the torch, returning the color and texture back to more of an original state.

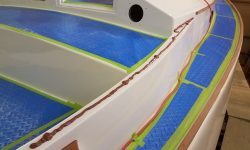

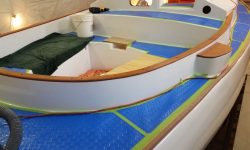

With all eight pieces fully prepared, I installed them for real in a bed of sealant.

To wrap things up, I tapped bungs into the screw holes, but held off removing the excess for now to avoid getting any chips into the fresh sealant.

Total time billed on this job today: 6.5 hours

0600 Weather Observation: 26°, clear. Forecast for the day: Mostly sunny, 44°, then a chance of rain in the evening