April 3, 2024

Calliope Girl 92

Wednesday

I continued work on the galley, using a template of the starboard face I’d made previously to cut out the plywood panel for the cabinet face. After some minor adjustments to the fit, I laid out for a single door opening, ultimately choosing one larger door versus two smaller ones because it seemed the best use of the space. I installed the panel with screws into the support cleats, and epoxy adhesive at the top edge where it met the overhead. I bunged the fastener holes thereafter.

After a final check of the spacing for the plate and glassware storage area, I templated and then cut a plywood panel for the divider, and installed it with epoxy adhesive all around so I could avoid bulky support cleats that would impede the space for the specific storage items intended.

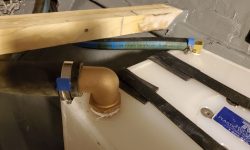

Next, I turned back to the water tank, and installed the fill and vent hoses, leading them forward into the chainlocker with some excess length to await final routing and connection to their skin fittings, which I planned to install later once the v-berth platform was in place to ease access to the chainlocker. At the aft end, I installed the supply lines leading from the tank to the water pressure pump, then on through a tee fitting to the head supply and a line to lead aft to a separate water filter that I’d soon install in the hanging locker.

This meant it was time to address the hanging locker. I’d removed two flimsy shelves earlier in the project, and now I measured for and installed some hardwood support cleats for new shelving, all of which would use the built-in hull stringers running through the compartment for support at the hull end; these stringers were appropriately placed and generally of level orientation. I chose to add cleats to the lower support as well, which would form a flat bottom in the compartment, hopefully more convenient for storage and also good for hiding and giving utility space to the hoses and wiring that needed to run through the locker to the forward cabin.

Next, I made some rough plywood templates of each shelf that I could use to build the three shelves required for the space. I transferred the patterns to 12mm plywood and cut out the shelves for a test-fit, but for some reason I have no photos of that part of the operation. In any event, they were ready to go, and I’d paint them separately before installation.

Meanwhile, I got on with what I really wanted to accomplish, which was to paint out the remainder of the locker so I could get to work on any final wiring and hose runs that had to run through or otherwise utilize the space.

Total time billed on this job today: 7.5 hours

0600 Weather Observation: 33°, mostly clear. Forecast for the day: Partly sunny, 44°