February 23, 2024

Calliope Girl 72

Friday

Job one was to install the large section of countertop, including the sink and faucet. After final preparations, including making sure the various supporting cleats were clean and ready for bonding, I set the countertop in place dry. I determined that I could move it enough to apply adhesive to the cleats for installation, then, with the countertop dry, I installed the faucet, working through the engine room from underneath. It would have been more fun to install the faucet down on the bench, but it worked out fine and access even with the countertop in final position wasn’t bad.

One small issue was with the braided supply hoses I’d purchased and installed on the faucet before installation. These hoses adapted between the compression threads on the sink supply lines and NPT threads at the other end, which I needed to connect to a hose nipple and thence to the water supply hose from the tank (eventually) (and a plug in the hot water line). However, when I tried to install the fixing nut and washers over these lines, along with the long sink hose that supplied the water to the pull-out faucet itself, I found that the total bulk was too large to all fit through the center of the fixing nut. It would have been far too fussy to try and install these hoses to the short ends of the supply lines extending from the faucet body in the space and with the access I had, so instead I removed the faucet and replaced the hoses I’d sourced with the original braided hoses that came with the faucet, which were smaller diameter with smaller ends. The minor down side was that I’d now have to go on a quest for the correct adaptation between the female compression end of the hose and the threads I needed, but I could take care of that later. I had a large supply of various plumbing fittings on hand but, as usual, I didn’t have what I actually needed now. The supply hoses hung down enough that I could reach the exposed ends easily for later connections. The smaller original hoses are shown in the boxed photo of the faucet below; the ones I had hoped to use are in the second faucet photo.

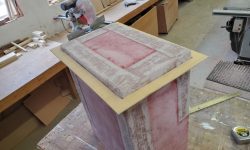

Plumbing thread frustration aside, the counter was now ready for final installation, so I moved it a bit as needed and applied adhesive sealant to all the faying surfaces of the cleats, using a generous amount and then chocking and clamping the countertop securely into position.

I realized I’d forgotten to Formicate the small section of countertop that extended across the back of the stove; I’d stored that small piece in a different pile and it had escaped notice till now. So I took care of installing the laminate on this piece, then installed it in its final position with sealant and clamps to hold it securely.

I needed to give the countertop plenty of time to cure–this would happen over the weekend–and in the meantime there was little else I could do in the galley. So I spent the remainder of the day on several smaller chores, starting with cleaning up the excess sealant (now cured) from the chainplates’ installation. Afterwards, I cleaned up the boat a bit and reorganized the cockpit to give me access to the port side locker, where I would soon be working on the propane locker installation. I also applied the second coat of finish paint on the back side of the refer locker front panel, completing that work.

I lightly sanded the interior tabbing I’d installed on the propane locker earlier, then made a quick plywood template of the box–including a 1-1/2″ wide flange around the edges to simulate the minimum flange I wanted to hang the box in place from the top–so I could check the fit on the now-accessible port cockpit locker. The hope had been to keep this locker as far aft as possible (the space tapered severely from forward to aft), but I was disappointed and surprised to find that even the minimally-dimensioned box, kept as small as practicable to hold the two small tanks, ended up further forward than expected. And the reality was that the opening would actually have to be a bit larger to allow the box to fit through at an angle.

This was disappointing because the owner had hoped–and I had expected–there to be space forward of the propane locker for a new top access to the large space beneath, formerly known as the quarterberth, but now it looked like this wouldn’t be possible after all. There might be space aft of the propane, but any potential opening there would be necessarily much smaller and less useful.

This was surprising because early in the project, after the owner suggested using the existing small pair of tanks rather than a new horizontal tank (which we had first considered), I had thought that given their seemingly diminutive size it seemed like they would have fit further aft in the space. But this proved not to be the case. At issue here really was an access problem: while there was technically space for the tanks and locker further aft, there was no way to install it from above, given the space limitations, and the nature of the space from beneath was such that installing the box from below, with a smaller access lid atop, simply wasn’t practicable. It was a tight and contortive space that would not afford the access required to do the work from beneath. This is why I’d always planned a top-only approach. I spent some time now re-evaluating this, but came to the same conclusion: there just wasn’t space to try and do this work from beneath. I could barely work in the old quarterberth space to paint and secure the old wiring, never mind messy and complicated glasswork above, around the bulk of the propane locker hanging down in the midst.

I’d actually hoped to begin the installation work by cutting out the cockpit seat as needed, but couldn’t proceed as is until I’d had a chance to discuss the findings with the owner.

To round out the day, I filled what little time was left with some prep and masking work in the head and forward cabin, preparing the overhead and liners there for primer and paint in the near future.

Total time billed on this job today: 7 hours

0600 Weather Observation: 36°, overcast. Forecast for the day: Rain and snow becoming all rain, 38°