February 2, 2021

Lyra 8

Tuesday

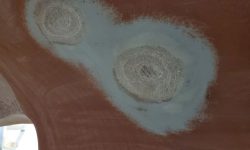

Beginning at floor level, I lightly sanded as needed the engine through hull patches, rendering them ready for final filling and fairing.

I continued with another round of light sanding on the transducer housing, which, other than a couple minor lows, brought this to a stage ready for the next steps, including installing some fiberglass, which I planned to get started on soon.

I spent the bulk of the day in the cockpit, sanding the rest of the seats, cabin bulkhead, coaming edges, and the cockpit well to remove the old coatings down to original gelcoat. I worked through two grits of paper in the process, leaving only the inaccessible corners to be dealt with during future sanding steps that would be underway presently. At the aft bulkhead, I prepared the edges of the large opening to the lazarette, which we planned to patch and fill in favor of a new opening in the poop deck.

I could have started the next rounds of sanding in the cockpit–corners and details–but decided instead to make the cut for the new hatch in the poop deck, which not only would provide better access to the space for various preparations and other tasks, but would also confirm the fit of the generator within, which I’d tentatively measured and thought would fit rather well. So I used the generator itself to make a simple cardboard pattern. Using a square held against the generator at its maximum dimension/protrusion on each of its four sides, I marked the cardboard accordingly, which gave me a rectangular pattern that would represent the minimum size of the hatch opening required. This was a starting point for the new hatch.

On deck, I measured in several places to determine the centerline (the backstay chainplate does not exit the hull on centerline), then laid out the template in an appropriate position near the forward edge of the space, and centered on the deck. An existing hole in the deck, leftover from a vent or some other installation, meant that I needed to slightly expand the width of the hatch to incorporate the old opening and obviate the need to patch it first; an additional 2″ width (to be duplicated on the other side for symmetry) took care of this, and I marked out the basic shape on the deck with a square.

Next, I cut out the deck with a saw, creating an expansive and accessible opening to the space within. I test-fit the generator in the space: plenty of room even allowing for some kind of platform, and as it stood now the handle of the generator stayed completely below deck level even with the generator standing nearly vertical. For the moment, the hatch opening was just barely wider than the generator, with minimum clearance, but I might need to make it a bit wider to accommodate the hatch surround/gutter. I’d deal with that in due course, but at least the storage idea had been confirmed as feasible.

Total time billed on this job today: 6 hours

0600 Weather Observation: 26°, snow and windy, several inches down overnight. Forecast for the day: Snow, maybe mixing with sleet, eventually ending, 30°.