April 20, 2021

Lyra 62

Tuesday

In the cockpit, I finished up with the installation of the starboard sheet winch.

Just aft, I installed a cleat for the roller furling line on a little pad that was already drilled for the cleat base (shown before cleanup).

I spent a good portion of the day working on the various installations on the poop deck, starting with the mooring cleats. Using old holes leftover from their previous installation, I installed these on each side with new fasteners and backing plates.

Next, I installed the stern chocks and a flagpole socket on the taffrail.

Since I was in the area, I remembered to bed and permanently install a through hull fitting for the bilge pump the owner had dry-installed on the starboard counter.

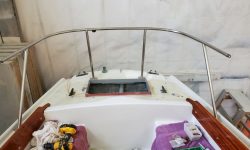

Now that the taffrail modification/repair was complete I could proceed with the final layout and installation of the stern pulpit. I started by centering the pulpit and getting the two aft bases where I wanted them, then secured each with a single screw for now through newly-tapped holes. Once the center of the pulpit was temporarily secured, I could lay out and mark the two forward bases, then remove the pulpit and drill, tap, and prepare all the fastener holes.

Afterwards, I installed the pulpit fully with new fasteners, sealant, and fiberglass backing plates, along with the plastic spacers I’d made for the forward bases. It would have been easier to install the forward bases before the locker lids were in place as I’d originally planned, but so goes the flow of a project; as it was, it was somewhat challenging to reach around the lids and under the deck to hold the fasteners and tighten the nuts below, but possible, if messier and slower than I’d like.

On the cabintop, I laid out for a main halyard winch, cleat, and turning block, following the owner’s chosen configuration. This part of the deck had not been previously repaired, and around the still-open bolt holes leftover from another hardware installation (where I planned to install the cleat), and a little bit forward, I found dark core when I overbored the fastener locations to fill with epoxy. The core was partly stained at the after winch holes, but clean at the forward holes. Further forward, where I prepared the holes for the cheek block, I found clean, good core.

In any event, after preparing all the future fastener locations with a 1/2″ bit, and masking the adjacent areas, I filled all the holes with a thickened epoxy mixture, leaving it to cure before continuing.

With new 48″ genoa tracks now on hand, I began to plan their installation. First, I had to clean up the decks on each side to give a reasonable bonding surface.

The tracks would be mounted outboard, near the gunwale, and the only lingering question was their fore and aft placement. On several sisterships I worked on previously, I’d installed identical 4′ tracks generally towards the forward end of the space between the center and after stanchions on each side, which placement worked well and afforded enough adjustment room for the typical genoa size of 120%-140%. Three iterations are shown below.

I proposed a similar location for Lyra, with the track aligned roughly as shown, but for the moment it was late in the day and I awaited input from the owner before I proceeded.

Total time billed on this job today: 6.5 hours

0600 Weather Observation: 32°, clear. Forecast for the day: Sunny, windy, 67°