March 2, 2021

Lyra 29

Tuesday

To begin the morning, I applied a second coat of paint to the two plywood bulkhead fillers.

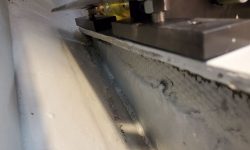

In the engine room, I’d left the engine in the state pictured below. Starting from this point, I eyeballed how I wanted to reconfigure the mounting flanges to get the shaft at the correct height and give room for adjustment in the mounting feet.

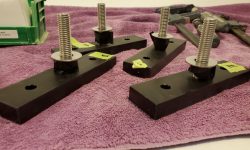

Removing the assembly once more to the nearby settee, I unbolted the flanges and, using the original spacers once more, reinstalled them with the vertical leg facing up, and at a slightly different height that would better suit the shaft position in the boat.

Replacing the engine on the foundations once more, I adjusted the mounts as needed to bring the two couplings into more or less perfect alignment.

Outside, I found that during the process the shaft had slipped aft by 3/8″ or so, which was a bit further than I wanted as it didn’t leave enough room to fit the propeller between the shaft and rudder, so after pulling things forward accordingly, I added a block of wood between the shaft and rudder to prevent it from moving again, and realigned the engine and coupling, clamping the forward mounts to prevent the assembly from slipping down the inclined foundations. Once I was finally satisfied with the position of everything, I made some marks outlining the position of each mounting foot on the beds, and labeled each foot for its position.

Now I could remove the electric motor, shaft, and stuffing box for final assembly. Down on the bench, I added 1/4″ graphite packing to the stuffing box (3 rings for now), and replaced the stock hose clamps with improved solid-band clamps. I permanently installed the shaft coupling with its key and setscrews, since I could slip this through the stern tube from inside the boat at this point, which I did next after installing the stuffing box.

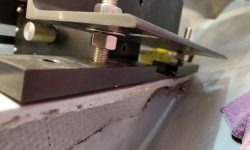

I wrapped tape around the lower adjusting nuts on each mounting foot, ostensibly to hold them in their proper adjustment when I removed them from the engine (this works better than not, but is not infallible), then, with each in place with its reference marks on the foundations, drilled the mounting holes and bolted the feet to the foundation.

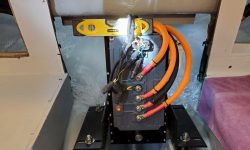

Now I installed the motor a final time, placing it over the mounting studs and, at more length than I expected, realigning it to the shaft coupling. I found that the tops of the foundations had a slight downward angle towards the outside, which, when the feet were bolted in place, caused some changes in the stud position and overall alignment. Fortunately, adjustments were relatively straightforward, since the motor was light enough to easily move, raise, or lower as needed, and eventually the couplings mated properly and, after securing the engine’s mounting nuts, I could finalize the shaft connection with the supplied bolts.

Finally, I reinstalled the L-shaped brackets I’d removed from the front of the housing earlier when I’d tried the previous mounting flange position. These little flanges would ultimately provide the basis for the front motor cover.

With the installation basics wrapped up within, I saw no reason not to install the propeller now.

The next item on the agenda, which I’d start forthwith, was the four large batteries required for the system. Using the boxes in which the batteries came–which served as decent analogs for the batteries themselves as they were a close fit in size–I mocked up the proposed battery positions as the owner and I had discussed: Two in front of the engine, where the box would also serve as a step for the companionway; and one each on either side of the engine, mounted either transversely or longitudinally (I thought transverse–long way across the boat as in the third photo–was more space-efficient). This project would continue next time.

Total time billed on this job today: 7 hours

0600 Weather Observation: 4°, high clouds and windy. Forecast for the day: Mostly sunny and windy, 16°