February 19, 2021

Lyra 22

Friday

In the cabin, I lightly sanded all the fresh primer to prepare for finish coats. This was a light scuffing by hand to remove the “grain” that the primer raised and to provide a generally smooth surface free from burrs and fiberglass texture. After sanding everything, I vacuumed and solvent-washed the entire area, leaving it ready for the next coat of paint.

This took all morning, and there wasn’t enough time to think about starting the paint after lunch, so instead I turned to the generator storage locker once more, starting by removing the fiberglass tab that had been in the way at the base of the existing compartment.

Next, I marked a new cut line on the aft side of the opening 3/8″ aft of the existing cut to provide ample room for the new hatch coaming, then cut the new line with a jig saw. Then, I cut the pieces of pre-made hatch coaming to length to fit tightly within the opening, overlapping the edges as planned. This was all fine, but the deck here actually had more camber than I expected–it looked and seemed flat or even sagging in the middle–which meant that the rabbetted area of the coamings didn’t work quite as intended, but nonetheless the pieces would still work fine, and where the rabbet ended up exposed at the sides of the opening I could make up with a fillet during final installation.

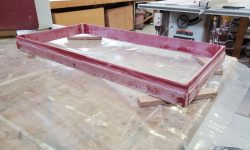

I’d originally planned to install the coaming pieces piece-by-piece in the opening, but as I dry fit it seemed to make more sense to temporarily glue the four sections together in the right orientation with some scrap wood hot-glued across each corner, after which I removed the whole assembly to the bench and finalized the connections with epoxy fillets at the corners.

The leftover bit of the original glassed-over plywood stiffeners exposed in the new opening on deck needed a little attention now also, as these had long ago debonded from their skins, so I filled the voids as necessary with some of the epoxy leftover from gluing the frame, clamped as needed, and coated the exposed plywood with more epoxy to seal it and prepare the opening for the coaming’s final installation soon.

In final works for the day, I carefully sanded the eight filled bolt holes in the transom to prepare them for the next steps. Also, new bronze flat bar stock I’d ordered for the chainplates arrived; the owner and I had decided it made sense to replace the original chainplates after I found a reasonably-priced source for the raw silicon bronze. The new stock was 3/16″ thick compared to the 1/8″ thick originals.

I’d still have to cut to size and shape and drill the holes in each chainplate, but because these were bronze it was something I could do easily enough at the shop.

Total time billed on this job today: 5 hours

0600 Weather Observation: 21°, cloudy. Forecast for the day: Another anemic excuse for a snow event, cloudy with a chance of light snow with little accumulation, 29°