February 6, 2021

Lyra 12

Saturday

To further advance the project in the coming week, I spent some time over the weekend preparing the stock for, and gluing up, the frame for the new forward hatch.

Using the hatch as a guide, I determined how much the hatch flange would overlap the frame: 1″ all around. I decided on a 1/2″ reveal, so that meant I needed to mill the stock to 1-1/2″ width. In due course, I milled a long blank from the original board to these dimensions.

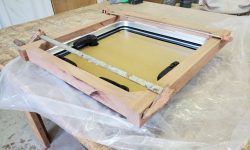

Using the hatch itself, I cut four pieces of the newly-dimensioned lumber to frame the hatch properly. I used tongue depressors as spacers between the hatch and the wood to provide a bit of leeway and provide for a close, but not overly tight, fit, and left two of the frame pieces overlong to make layout easier and since the corners of the frame would later be trimmed to a curve that matched the hatch radius anyway.

At the inside corners of the frame, I cut angled bits of wood to fit closely to the hatch curvature.

I made reference marks at all four corners to help align the pieces for gluing, then, after solvent-washing the pieces to clean them, glued up the frame with thickened epoxy adhesive. With the frame bottom side up, I clamped it securely to the table to keep things nice and flat. The angled blocks in the corners, in addition to filling in the space, also added gluing area and additional strength to the joints. At three of the four corners, I used light clamping pressure to pull the blocks into the corners; at the fourth corner, where I couldn’t directly clamp the frame to the table, I found that attempts to clamp the corner block tended to pull the joint out of alignment, so I left that block unclamped. I left the frame to cure fully.

Total time billed on this job today: 1.25 hours

0600 Weather Observation: 30°, cloudy, snow shower or two. Forecast for the day: Clearing, 35°.