February 29, 2016

Salty 5

Monday

During the weekend, I moved the most recently-completed project out of the shop to make way for Salty. I left the winter cover in place till she was indoors, but later I removed and stored the cover, and removed the wooden frame to prepare for the project ahead.

I began by leveling the boat from side to side.

The hull was in good condition overall, and at this time no significant cosmetic work was planned. The surface appeared to be factory gelcoat, but it was in good condition and appeared to have been generally well-maintained.

The decks, also in original gelcoat and molded nonskid, were in good condition, with the usual collection of dirt and oxidation. Again, no major cosmetic work was planned at this time.

The interior was also in overall good condition, and once more cosmetic concerns were not part of the project at this time. Instead, most of the work would focus on the boat’s systems and equipment sides, which, as we will see, required more attention. After documenting the starting condition of the boat, I removed excess gear from the cabin and elsewhere to prepare for the work ahead.

Next, I set up staging around the boat at deck height. Because the boat was narrow, with tight sidedecks, I could reach most parts of the deck from the comfort of the staging, and work would be easier there for whatever deck-related work was required.

The boat’s previous owner had installed a Wallas 1500 cabin heater in an awkward location in the narrow passageway, right below deck level, a necessary compromise for this sort of unit in a small boat like this. However, the new owner planned to revamp the interior heating situation with a special add-on blower lid for the cookstove (more on this later), so the old heater was now obsolete, and I made it my first priority to remove it and clear the way.

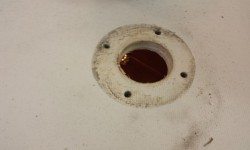

Removal was fairly straightforward. The heater was plumbed to a portable fuel jug inside the locker, and it was easy to remove the fuel lines and electrical service. Then, the heating unit itself came off its mounting bracket with ease, and the bracket itself was simply screwed to the bulkhead. With the heater out of the way, I could remove the Charlie Noble fitting from the deck; this was secured with four bolts. Fortunately, the nuts came off without spinning the bolts, as I couldn’t easily figure out how to remove the top of the vent fitting to access the screw heads on deck, even though I researched the part briefly first. As it happened it was a non-issue, and soon all that was left was a neat hole in the deck, which I’d patch in due course.

The galley was equipped with a Wallas 85DP cooktop, also fueled with a small fuel jug beneath. The stove itself was not permanently installed, and with the anticipated modification to install a Wallas blower lid–which, when lowered, allowed the cooktop to act as a hot-air cabin heater–I decided to remove the stove to make the modification easier. The blower lid was a neat idea since it made efficient use of limited space in the cabin, and would surely provide ample heating power for such a small boat. I’d work on that installation presently.

One of the main tasks on the work list for this project was to revamp the entire electrical system, with new wiring and various fixtures, along with new LED interior lighting. To that end, I began disassembly, removing the interior lamps and unscrewing the electrical panels to get a look at the existing wiring situation and plan for the work ahead. Removal of the remaining wiring and such would continue in the days ahead.

The other major project that formed the core of the job was installing a new diesel and revamping all related systems, as well as other plumbing systems on board. In the time since I removed the old diesel several months earlier, the owner had decided to replace it with a new engine rather than continue to pursue rebuilding options, and this work would consume most of the time and resources allotted to this project. So in the near future, I’d remove extraneous and outdated equipment from the engine room, and soon the boat would be down to a clean slate for the new installations to come.

Total time billed on this job today: 8.75 hours

0600 Weather Report:

20°, mostly clear. Forecast for the day: sunny, then chance of showers later, high in the 50s.