March 7, 2016

Salty 10

Monday

After removing a final piece of hardware (at least for this particular round) from the starboard sidedeck, which had resisted efforts last time (and I’d run out of time before I could finish it), I prepared all the hardware locations by boring 1/2″ holes at each fastener location (this kept the larger hole within the footprint of the hardware in all instances), which removed the core material (plywood) from about the fasteners for future core isolation. I also cleaned off old sealant from the deck and hardware bases. Then, I masked around the holes (and from the underside of the deck) to prepare for epoxy filling.

Next, I filled all the prepared holes with a thickened epoxy mixture, and removed the tape afterwards.

At the bow, I removed the anchor, chain, and rode from the roller and anchor well, exposing a filthy anchor locker that I cleaned up afterwards.

At the mast step, I removed three old wiring fittings, which we’d not be reusing, and prepared the holes for patching. For cosmetic reasons on the molded nonskid pattern, I’d be building a simple cover to secure to the deck over the patched holes (the undersides were hidden in a wooden trim box).

I took this opportunity to clean off unsightly gobs of old sealant from around and the top of the mast step plate, which was head-scratchingly secured into a molded recess in the deck that, frankly, seemed only like a trap for water and offered no benefits whatever. This process exposed a pre-existing crack in the aft starboard corner of the plate, which didn’t appear to cause any structural concerns with the integrity of the step itself, but made me wary of attempting any further removal of the step for rebedding, since there was hardly any way to get under the piece anyway thanks to the recess, and I worried the casting might fall to pieces if I tried. Sometimes well enough is best left alone. With a cleaned-out groove about the step I could later refill with new sealant applied in a more uniform manner, and perhaps force some epoxy into the aft corner to shore up the crack.

Next, I masked around the old wiring holes (now prepared for filling), and, nearby, around the hole left over from the old cabin heater vent. I filled these voids with thickened epoxy–the wiring holes as a permanent closure, and the old vent hole as a temporary means of providing a place for a hole saw to enlarge the opening, since we’d decided to install a solar deck vent in its place, which required a larger opening.

Following my inspection of the through hull fittings earlier, the owner had requested that I change out all the underwater fittings with new bronze through hulls and flanged seacocks to replace the ill-threaded valves directly on the existing through hull necks. However, since the outlets were above the waterline, we decided to keep the two through hulls that had serviced the bilge pump outlets and simply replace the valves inside with new bronze ones. So I got started in the cockpit locker, and removed the two valves from those through hulls, pending arrival of the new valves later. Fortunately the valves unthreaded without any particular issue.

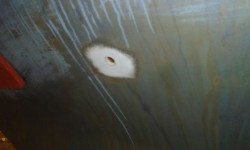

Moving on to the cockpit scupper drains, after a brief attempt to unthread the valves and through-hull nuts from inside, I quickly gave that up as a waste of time and, with a reciprocating saw, simply cut the through hulls off from inside, working the blade through the wooden backing blocks and quickly through the fittings themselves, after which I could remove the remnants of the plywood blocks and push the through hull fitting out from inside.

I continued with the engine raw water intake, located at the forward end of the engine room to port. This fitting featured an external bronze strainer, which I removed for access to the through hull beneath.

In similar fashion, I removed the galley sink drain, and the heat intake and overboard fittings.

Afterwards, to prepare for new installations I sanded away the paint from the outside of every fitting, and any remnants of old sealant, adhesive, and factory interior gelcoat on the inside of the hull at all locations. Sometime soon I’d finish the basic prep work by cleaning out any sealant remaining in the old through hull holes themselves, but for now the day was over.

Total time billed on this job today: 8.5 hours

0600 Weather Report:

20°, partly cloudy. Forecast for the day: mostly cloudy, chance of snow and rain showers, high around 40°