November 30, 2022

Holby 57

Wednesday

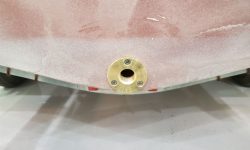

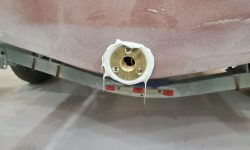

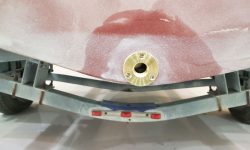

Now that the construction and painting was complete, I turned to some of the hardware reinstallation–or new installation, in some cases. I started with some specifications and ordering to replace some of the older electrical items from the console, including a new circuit breaker switch panel and VHF radio that I’d flush-mount in the console. Afterwards, I got to work on the boat with the new bronze garboard drain fitting. I marked, drilled, and tapped the fastener locations and dry-fit the piece with temporary screws before installing it permanently with plenty of sealant and bronze screws.

I installed new stainless steel end caps to finish off the rubrail at the transom.

Next, I reinstalled the original transom U-bolts.

I installed four sets of scupper flaps over the cockpit scupper openings (secured with screws to the exposed ends of the plastic through hull fittings) and over the outboard well drains (secured to the hull with sealant and screws).

Next, I turned to the bilge pump. When I removed the relatively new pump at the beginning of the project, I’d labeled its various wires, so now I reinstalled the pump base platform on the little raised wooden support in the bilge (leftover from before), then cleaned up and rewired the pump according to the original wire positions. Preparing ahead to secure the wire harness to the boat well above the level of future bilge water, I sanded away the paint from a couple spots inside the bilge area, then installed wire tie mounts with an acrylic adhesive, leaving these to cure overnight before securing the wires.

I attached a new outlet hose to the pump and led it into the port aft locker, beneath the seat. The original pump had included a siphon break loop, which I planned to reinstall. I didn’t want to fasten this through the bulkhead as it had been before (when the now-open outboard well was part of an enclosed engine room), so to prepare for mounting the siphon break I epoxied a fiberglass block, into which I’d drilled and tapped fastener holes for the hardware, to the side wall of the locker, leaving this to cure overnight. I also ordered a new through hull fitting for the pump outlet to replace the old, damaged one that I’d removed at the beginning of the project.

Finally, I lightly sanded the paint on the field area of the livewell hatch, masked off the borders as needed, and applied nonskid in the same color, with a flattening agent added along with the nonskid particles, to finish off the work on the hatch refurbishment.

Total time billed on this job today: 7 hours

0600 Weather Observation: 0600 Weather Observation: 34°, overcast, dew point 26°. Forecast for the day: Rain, windy, 53°