April 13, 2022

Holby 11

Wednesday

The rough cut for the transom cutout was fairly accurate where it counted, on the transom surface, but inevitably the blade had wandered through the thickness of the transom, leaving several areas higher than desired on the inward face.

Now, with a saw, grinder, and various sanding tools, I cleaned up these areas, and brought the cutout right to the layout line on the wooden transom as needed, leaving a mostly flat and clean-enough-for-now shape all around. There’d be ample opportunity to further refine the opening coming up, but for the moment my goal was to clean it up sufficiently to the layout lines so I could move on to removing the wood veneer from the transom.

The teak planks on the transom were about 3/8″ thick, with an overlapping solid teak rubrail at the top corners, integrated with (specifically glued to) the teak coaming cap. The planks and trim were glued to the transom with a resinous adhesive, presumably epoxy, and several screws beneath bunged holes. To begin, I used a chisel to expose the screw heads on the trim, and removed the screws. When attempting to chisel out the trim piece, I quickly found that it risked damaging the coverboard above (which we planned to keep if possible), so I used an oscillating multi tool to cut along the glue line between the trim and the coverboard, after which I could chisel out most of the trim.

Then, as a sort of trial run at removing the teak over the transom field (I was expecting a transport truck to move a boat shortly), I began chiseling out the wood starting at the transom cutout. The wood was well-adhered to the transom all over, and clearly removal would simply be a matter of literally chipping away at it.

With the departure of the boat in the next bay, I took the opportunity to move this boat to my preferred and dedicated work bay for the duration of the project.

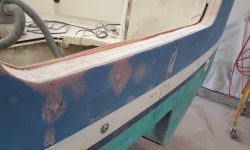

Once I got set back up, I worked the remainder of the day to remove the teak from the transom. It was a necessarily destructive process, possibly sacrilege, but there was nothing for it but to chisel off the boards however they came. I found that it worked better if I chiseled across the grain–vertically, in this case, and while it seemed slow during the process, it actually didn’t take too long before the remnants of the transom and rubrail trim littered the floor beneath the boat, leaving behind a layer of wood of variable, but minimal as practicable, thickness. Some damage to the fiberglass was inevitable, but I tried to minimize it in favor of leaving a bit more wood behind to be dealt with next.

To finish, I sanded away the wood and adhesive reside, bringing the transom back to its original gelcoat. There’d be some minor repairs required, but there was plenty of structural work to come around the cutout as well and overall the transom fared well. There’d be additional work required at the top edge in terms of finalizing the profile of the coverboard and covering the now-exposed hull-deck seam there, but the way forward there would become clear as the project progressed.

Total time billed on this job today: 5 hours

0600 Weather Observation: 42°, mostly clear. Forecast for the day: Partly sunny, 59°.