October 20, 2022

Holby 37

Thursday

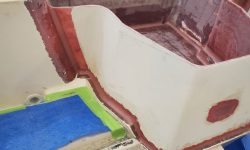

I prepared the outboard well and bulkhead for the next steps, removing the glue blocks, water-washing the epoxy, and lightly sanding the pre-fillets as needed. Afterwards, I laid out and measured or cut fiberglass tabbing for all areas as required.

With that done, I applied new, larger, final fillets to both sides of the bulkhead and around the perimeter of the well deck. I left the epoxy to partially cure while I finished up cutting the tabbing as needed.

Once the epoxy fillets had cured past the mushy state, I wet out and installed the tabbing, starting at the forward end, from the cockpit. Here, I only used a single layer at the edges where the bulkhead met the existing structure, to avoid excess fairing in the most visible cosmetic area; the aft-facing side of the bulkhead is where all the actual structure, in the form of extra fiberglass, would be. Around the forward three sides of the bulkhead, I applied no fiberglass as there wasn’t enough room on the narrow ledge to make it worthwhile; again, the structural component would be on the back side. I installed two layers over the opening that had once held a handhold for the original engine box.

On the other side, I applied two layers of tabbing to all the seams and around the aft edge of the outboard deck, securing the bulkhead assembly and the deck to each other and to the adjacent areas of the boat as applicable. This entire structure would also greatly reinforce the transom against its new-found outboard-related stresses. I left the new fiberglass to fully cure; later I’d fair in all this new work to create a cosmetically-pleasing well.

Total time billed on this job today: 4.5 hours

0600 Weather Observation: 33°, clear. Forecast for the day: Mostly sunny, 55°