May 6, 2022

Holby 22

Friday

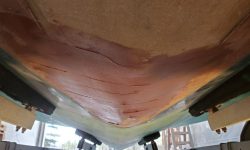

After a light sanding and other preparation at the forward vee portion of the repair, I applied a second round of fairing filler to take care of t he low spots left by the first-round troweling. These efforts were designed to recreate the basic shape of the previously-flat spot on the hull, and with the second round it appeared close to the final shape needed before I could fiberglass over the whole area.

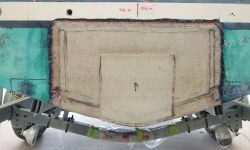

I had some fairing compound leftover, so I applied it to portions of the transom that were damaged during the wood veneer removal.

At the transom, I’d hoped to laminate three layers of cloth over the entire vertical transom repair, and overlapped 9″ onto the bottom, which would allow me to offset the three layers by 3″ each to provide overlapping room for the fiberglass to continue forward over the remainder of the bottom repair. However, I simply couldn’t make the cloth take the required shape, what with the V-shape, not without huge and unwanted darts and cutouts in the cloth, so I changed my plan to one that would work. I kept the 9″ overlap on the bottom (with the subsequent two layers spaced 3″ back in each case), but reduced how far up the vertical transom they came, with the largest layer extending 3″ up, and the remaining two staggered 1″ down. I could make the cloth conform to this shape.

Above this, I installed three layers over the vertical part of the repair, butting the first layer against the upturned bottom layers, then overlapping the subsequent two layers appropriately over their staggered counterparts below. I finished off the transom fiberglass for now with two smaller layers that filled the slight depression over the vertical part of the old jet tunnel, bringing this area nearly flush with the surrounds. I let these layers hang just below the bottom for later trimming.

To round out work for the day, I installed six layers of 1708 over the top edge of the transom cutout, which would increase the height a bit to bring it closer to the required 24″ from the bottom of the vee when all was said and done. Later I’d wrap more fiberglass over the entire cutout, which would bring the height up to the final dimension as well as tie it in the new cutout and complete the work there. I let the strips of fiberglass overhang the opening a bit for later trimming, and used some thickened epoxy at the ends to reform the curved shape at each lower corner.

Total time billed on this job today: 5.25 hours

0600 Weather Observation: 39°, clear. Forecast for the day: Mostly sunny, 63°