May 4, 2022

Holby 20

Wednesday

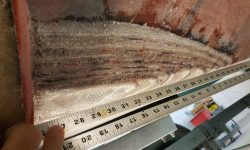

I lightly sanded the new fiberglass on the forward vee part of the bottom, then, after cleaning, used a straightedge to check how I was doing, height-wise. Obviously I knew it was low at the aft end, but this gave me an indication where the additional layers should stop at the forward end; I also used the straightedge to determine how wide the new layers should be at the aft end, i.e. where the existing fiberglass was already close to the proper geometry.

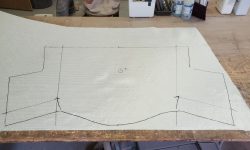

With this information, I made a new pattern and cut seven new layers, this time keeping the aft ends’ widths more constant while continuing to taper back the forward sides and end. Because the new layers would overlap the stacked, tapered layers beneath, I skim-coated some thickened epoxy over the existing patch just to ease the transitions between the cured layers.

Afterwards I wet out and installed the seven new layers, which brought the finished rough shape close to what I needed, and just low enough that I could finalize the shape with fairing compound once cured and before fiberglassing over the whole area.

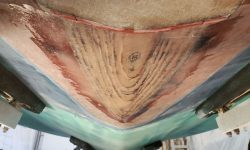

Meanwhile, I made a pattern of the inside of the transom for layers of fiberglass that would cover the entire transom and extend onto the bottom of the hull and along the sides to tie everything together. Once I had the pattern made, I installed epoxy fillets as needed around some of the corners and wet out the whole area, leaving this to tack up while I cut two layers of fiberglass according to the pattern; then I wet out and installed them.

Continuing the work on the vertical part of the jet tunnel in the transom, I cut 10 layers of fiberglass to fit, as I still had an inch and a half or so of depth to fill. I prepared epoxy fillets along the bottom corners to ease the transition beneath the core pieces I’d installed earlier, then, in stages, installed the 10 layers of fiberglass in the space.

Later in the day, this had cured enough that I could install another layer of 3/4″ Corecell over the fresh laminate, bringing the area out nearly flush with the surrounding fiberglass. I installed a couple braces to hold the core tightly along the bottom, where it wanted to spring out slightly. From here, once cured, I could start installing the fiberglass over the whole area that would finish off the repair and tie it in with adjacent structures.

Total time billed on this job today: 6.25 hours

0600 Weather Observation: 46°, cloudy, light rain showers. Forecast for the day: Rain and showers, 51°