October 28, 2015

Aventura 18

Wednesday

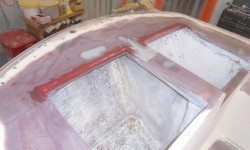

My days of beginning with sanding chores were winding down–at least in the very short term–but once more I started by sanding the new fiberglass work from last time, including a light scuffing of the new tabbing in the interior (cockpit gutter system and mast support structure), which simply removed any sharp edges and prepared these areas for eventual paint. At the poop deck, I sanded the newly built-up areas at the aft ends of the hatch openings, and trimmed the overhanging material from the aft corners to complete the basic construction.

After the usual cleanup, I applied more epoxy fairing compound to the fillets to better transition the raised areas into the surrounding decks.

After taking a few hours to work with the contractor building custom covers for two of the boats outdoors, I returned to the shop in the afternoon and continued working down my pre-primer punch list. Around the perimeter of the deck, I cleaned up the edges near the vinyl rubrail where the mechanical sanders couldn’t reach, and cleaned up the top surface of the rubrail to prepare it for the eventual toerail installation. I’d been putting this minor chore off long enough, and in the end it didn’t take too long to complete.

Meanwhile, I pulled out some of the deck hardware from storage so I could mark the fastener locations. In the cored areas of the deck, I’d overbored and filled the fastener holes for the bow mooring cleat and a fairlead on each side deck, and to avoid losing the original locations–which were now fully prepared for hardware installation later–I aligned the hardware and drilled small pilot holes that would help mark these locations during the painting process. It was only these three pieces, as all other locations either had their original holes (and were not in cored areas of the deck), or else I could easily relocate the hardware without the reference, such as the mainsheet blocks and stern cleat.

I planned to reuse the original deadlight frames (plastic), so I carefully removed the acrylic lenses from the frames and cleaned up the old sealant from the lens area, as well as the back surface of the ports where they bonded to the boat. I’d prime and paint the frames to match the deck.

I cleaned up as needed the epoxy fillets securing the three fiberglass through hull pads I’d installed earlier, as well as the actual holes through the hull, and worked on the first steps towards final installation of the new hardware. At each location, I taped the through hull in place from the outside, then, from inside, threaded on the flange base to determine how much the through hull necks would need to be shortened in order to allow the flange to thread completely on. I marked where the through hull passed through the base place for reference and removed the fittings for trimming.

While in the boat, I lightly threaded on the valve body and 90° hose fittings required at the two scupper locations to make sure there was clearance to install these after the flange bases were in place. There was plenty of clearance.

Back on the bench, for each of the three fittings I threaded the flange base fully on, then measured the distance between its base and the mark on the through hull neck. Then, allowing some extra to ensure full threading, I marked and cut off the excess length before cleaning up the thread ends to allow the flange base to thread on easily. I wasted a lot of time removing the manufacturer’s stick-on labels, unhelpfully attached to the through hull threads and which, through various storage and shipment, had become impregnated into the deep parts of the threads, preventing easy threading and all of which had to be scraped and brushed out to allow the fittings to be used. I wasn’t at all impatient with this necessary–but should have been unnecessary–chore. In the event, the through hulls were now ready for final installation, which I’d take care of next.

Total time billed on this job today: 5.25 hours

0600 Weather Report:

22 °, clear, calm. Forecast for the day: increasing clouds, rain by evening, 50.