March 30, 2022

Holby 1

Wednesday

The owner of this boat purchased it knowing he wanted to reconfigure from the existing gasoline inboard/jet drive propulsion unit to a modern outboard, along with associated and general upgrades and cosmetic improvements. This would be a longer-term project, with work beginning now (the owner had recently delivered the boat to the shop), but extending into the fall work season and beyond as needed given previously-scheduled projects.

With time on the schedule immediately, I started work by moving the boat into the shop and removing the shrinkwrap so I could get my first look at everything.

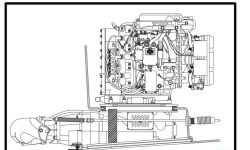

The existing engine and jet drive was a Mercury 175 Sportjet, a hybrid of a regular V6 outboard engine and vertically-driven jet pump in place of the leg and lower unit of the outboard. This was the first of these I’d encountered, and my first steps included as much online research as possible to determine how the parts were connected and how to remove them properly. I found a schematic or two, and various pictures of units for sale elsewhere that helped me understand how the parts fit together and how to remove them, at least to begin. The engine was paired to a vertical shaft in the pump housing below and secured with 8 bolts to the adapter/mounting plate. Removal would require first removing the engine, then the drive itself.

The photos below are images of a similar jet drive that I found on the internet, shown only for reference and educational purposes.

The blue tape on the transom represents the owner’s template, based on measurements he took from a sistership, of the approximate proposed outboard cutout, but we’d be taking additional steps to confirm the measurements before making any cuts.

Further inspection of the engine compartment and adjacent areas revealed the bolts to be removed, along with ancillary equipment I could remove to improve access (and which all had to be removed for the conversion anyway).

I spent a brief time looking over the entire boat in general. Two engine room vents (which would no longer be needed after the conversion) on the stern quarters were just sitting in their openings with no fasteners, so were easy to remove for a look at the hull structure, which appeared to be an Airex-cored laminate. I’d spend more time presently to inspect the entire hull in additional detail to look for any “deal-breaking” issues before proceeding with the real work.

Total time billed on this job today: 1.75 hours

0600 Weather Observation: 26°, clear. Forecast for the day: Sunny, 47°.