March 7, 2017

Halcyon 48

Tuesday

The two main countertop areas at the galley and the head required resurfacing with fresh laminate to update and freshen the appearance. The owners chose a beige color to coordinate with the general color scheme on deck and that which was planned below, and to offset the clean white color of the interior. While the mechanics of resurfacing were straightforward, the confined nature of the surfaces in question, penned in by bulkheads on both sides and with other obstructions, meant that in order to install a new surface I’d need to build accurate templates so I could pre-cut the laminate exactly to size, rather than trimming it flush after gluing. Much earlier, I’d looked into removing the countertops from the boat to make fabrication easier, but had long ago determined that this was not a feasible proposition.

On the head side, there was just a small section of fixed countertop, at the outer edge of the space next to the hull. This section of countertop ended just shy of the bulkheads at some flush wooden trim, so the new piece needed to stay within the same bounds.

On the galley side, the countertop pattern would be complicated further by the fact that the icebox opening was partially beneath a shelf, and my trim router wouldn’t fit beneath. So not only would I have to pre-cut the main countertop, but I’d also have to pre-cut the opening for the icebox, at least in part. The shelf was bolted in place to a little fiberglass flange, and I quickly decided it wasn’t worth the frustration and time to remove versus making a more accurate template.

I started with basic paper templates of the countertops. I used a steel ruler (and dividers at the curved hull end) to mark an offset on the paper pattern, making for easy transfer to some plywood for the actual cutting pattern. I made rubbings of the sink and icebox openings, along with the hole for the water pump, to make locating them easy later on. On the head side, I did the same thing, but this was a much simpler space and only required the offset to mark the edges.

The plywood patterns needed to be thick enough to provide a bearing surface for the guide on the router bit that would actually cut the countertop, so I used scraps of 12mm plywood that I had around. The head pattern was simple and quick to transfer to an appropriate scrap of plywood.

Not wanting to wantonly waste the material, I decided I only needed a “real” pattern of just the outermost portion of the galley countertop, incorporating the curvature of the hull and the portion of the icebox opening that was inaccessible (for the router) beneath the little shelf. Once I had the main shape cut out (and one round of fine-tuning when I test-fit it), I found I could trace the inside of the icebox opening directly on the bottom of the pattern, making an accurate cutout simple.

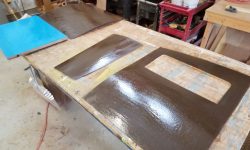

Using additional plywood for support and as a straightedge for the pattern router bit, I cut out the sheets for the two sections of countertop. test-fitting them in their respective spaces afterwards. I initlally left the galley sheet overlong, so I could mark–and then accurately trim–the inboard edge at the proper location. I cut out only enough of the material at the icebox to allow me to finish the trimming once the countertop was glued in place. along with the sink opening.

I’d previously scuffed the existing countertops with coarse sandpaper to prepare them, so after final cleanup I applied contact cement to the surfaces, including the hinged section of the head area that I could work on at the bench. Once the cement dried, I installed the countertops, and used my little router to trim out the icebox and sink openings. I made a rough hole for the sink pump, but I’d finish that up a little later. A couple other small pieces, including the icebox lid and a sliding shelf from above the head, remained to be completed, but I’d do those just a little later.

Now I installed a new length of piano hinge on the head countertop, reinstalled its mahogany trim that I’d refinished before, and then attached the other side of the hinge to the fixed portion of the counter in the boat, completing the installation there. Meanwhile, I dry-fit some of the varnished edge trim that I’d refinished to check the fit, but I’d await its installation till I finished one or two other things, mainly the sink pump installation.

A shipment of old Sailmaster parts arrived, including various deck cleats that I needed to replace some of the damaged ones from this boat, and, most importantly, two nice examples of the damaged port quarter chock. Now I could pick and choose amongst the best pieces to finish up the hardware and ports’ installation in the coming days.

Total time billed on this job today: 6.5 hours

0600 Weather Observation:

Light snow, 26°. Forecast for the day: light snow/rain showers, temperature rising through the 30s