February 24, 2017

Halcyon 41

Friday

The owners requested that I install a portable toilet in the original head compartment. To accommodate the porta-potty, the space required a platform, as the original small platform that had supported the long-removed marine head was not suitable by itself.

I obtained the smallest possible porta-potty, and even so the fit was surprisingly tight, given the confines of the space between the curvature of the hull, the depth of the toilet, and the height of the space beneath the hinged countertop/cover. However tight, I determined that the new unit would indeed fit, and with the actual toilet mocked up I made one reference mark on the hull to show the maximum height of the new support platform.

From here, I made up a cardboard template to get the basic shape required, then transferred this to a piece of scrap luaun plywood for a more accurate template and to double-check the fit. I leveled the platform in both directions.

I checked the fit of the toilet, ensuring that it not only fit inside of the curve of the hull, but also cleared the hinged countertop, as well as the cleats that demarked the inside of the longitudinal panel that would close off the passageway-side of the opening later.

After making some final layout marks on the template, I transferred the shape to some 12mm marine plywood and cut out the plat form. I sharply beveled the outer edge of the platform to conform to the curve of the hull and ensure that the top of the platform ended up at my original layout line on the hull–the one sweet spot that allowed the small toilet to fit both height-wise and transversely. I checked the fit of the new porta-potty with all the various panels in place once more to ensure that the fit was as anticipated and as required.

To install the platform, once it was properly positioned I made reference marks on the bulkheads, then installed support cleats fore and aft. Before permanently mounting the platform, I painted out the space beneath, which would be inaccessible going forward. I also epoxy-coated the underside and edge of the new platform. I’d paint out the remainder of the space later, once the platform was permanently secured.

I installed the platform permanently with some thickened epoxy on the cleats and where the platform met the hull, then added a strip of tabbing to further secure the platform, leaving the fiberglass to cure overnight.

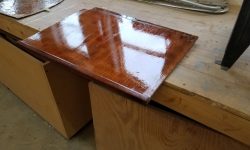

Later, I lightly sanded and varnished anew the various trim pieces, panels, and cabin sole sections, continuing the base coat buildup.

Total time billed on this job today: 4 hours

0600 Weather Observation:

33°, clear. Forecast for the day: sun and clouds, 50