September 26, 2016

Acadia 6

Monday

With a late start to the day after a morning meeting, a light sanding of the hull patches, which I’d begun fairing in last time, prepared them for a second round of epoxy fairing filler, mainly to fill small voids in the initial coat.

Back in the engine room, I returned to the bulkhead modification required on the port side, where the fresh water pump hoses led. To release the hoses from their slotted passage through the bulkhead, I cut an opening from the side, allowing me to slide the hoses and pump out of the way without disconnecting anything. While this system might end up being reconfigured later, for now the prudent action was to leave it as is pending further decisions.

With the hoses and pump now clear of the bulkhead, I marked a cut line, just over 3″ in from the existing edge (this matched the distance from centerline of the vertical edge of the companion starboard bulkhead), and cut away the excess bulkhead to improve clearance for the new engine foundation. I’d clean up the remnants of tabbing a little later.

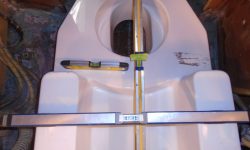

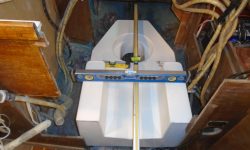

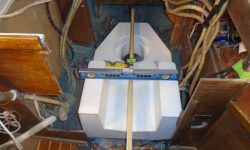

With ample room now in the engine compartment, I set up the molded engine foundation and leveled it from side to side and longitudinally (according to the cabin sole, which position I marked on the level with some tape for easy replication). After some minor fine-tuning of the fore-and-aft position of the foundation and centering it on the boat, I determined that the highest point was about 5″ above the hull, so to trim the foundation I marked 5″ from the hull at various points around the foundation’s perimeter. Space was too tight or awkward in most areas to effectively use a scribe, but the 5″ markings would give me enough information for the initial cut.

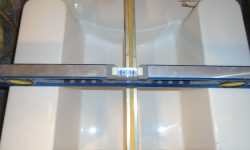

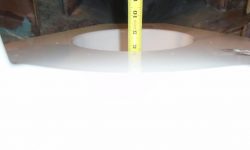

I removed the foundation down to the workbench and connected the various marks with a straightedge and marker, forming a cut line. At the oval molding for the drive leg, where I’d made my reference marks on the inside (white side). I transferred the marks to the outer (laminate) side since there was no way to get a saw inside the opening, and roughed in the contour of the cut line.

With a jigsaw and carbide blade, I cut to the lines all around.

With the foundation back in the boat, I set it up again in the engine room, aligning it as before with several levels. This highlighted a few areas requiring some additional trimming, as I couldn’t get the aft end of the foundation down far enough. The contact points seemed to be at the aft corners of the leg molding, as well as a spot on the after starboard side of the foundation. A couple rounds of trimming, and I could get the foundation positioned properly according to the levels. I made some marks on the hull to allow me to easily reposition the foundation, as there’d be a few more rounds of in-and-out ahead.

This trimming was enough to allow the foundation to fit more or less closely with the contours of the hull, but a critical measurement remained: final depth of the drive leg for proper propeller clearance beneath the hull. The propeller was 14″ diameter, and I wanted to end up with around 1-1/2″ clearance between the blade tip and hull as a minimum. So after consulting the drive leg itself for a visual reference and for a good measuring point (which turned out to be the base of the transmission mounting flange, which equated to the top of the foundation), I measured down to the hull at a couple points to determine the highest point of the foundation as currently positioned, which was around 7-5/8″.

I measured from the mounting flange down this amount on the drive leg, and made a small reference mark. Then, from the center of the prop shaft, I measured up 7″, the radius of the propeller, and made a second mark. This gave me just about 2″ of clearance, not accounting yet for the hull thickness, which I did not yet know, but for now I allowed about an inch for hull thickness at the centerline, giving me perhaps an inch of blade clearance as currently configured, and guessing at the thickness of the hull.

There was room to easily bring down the foundation by at least an inch, which would improve blade clearance accordingly, and this would also allow me to fine-tune and (hopefully) properly scribe the foundation to the hull, so that would be my next task, but for now I’d reached the end of the day.

Total time billed on this job today: 4.5 hours

0600 Weather Observation:

32°, clear. Forecast for the day: sunny, around 60.