October 24, 2016

Acadia 22

Monday

Now that the engine room paint had cured over the weekend, I removed the masking tape, leaving the space ready for final installations.

I led several new hoses from the lazarette into the engine room: two hoses to connect to the existing bilge pump lines, and two lengths of vent hose for the blower output and a fresh air intake, both of which would eventually connect to a pair of clamshell vents on the aft cockpit coamings. I led all these hoses in now while I still had access to the aft bulkhead and beneath the fuel tank. I left the excess hose in the lazarette for later connection; for the moment, I just wanted them led into the engine room so I could move forward there.

With that complete, I made up the final connections for the bilge pump hoses, connecting them to the existing lengths in the engine room, and led over the final length of new hose from the reconfiguration of the fresh water system, which I secured along the forward edge of the foundation and connected to the tee before the water pump. Meanwhile, I resecured the water hose bundle on the port side, which I’d moved temporarily while I glassed and painted the foundation.

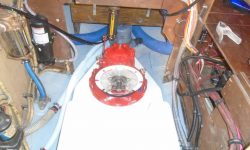

I kept the blower/vent hoses out of the way for now, and installed the waterlift muffler on its platform before connecting the existing length of exhaust hose with a short splice of new hose to reach the muffler outlet.

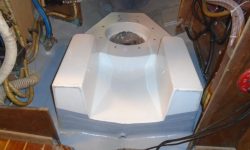

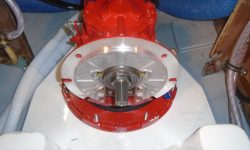

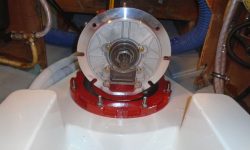

With these final preparatory installations out of the way, I could install the transmission and drive leg permanently. I cleaned the top of the foundation as needed to ensure a good sealing surface for the rubber gasket on the unit, then installed the transmission without difficulty, twisting it into place in the correct orientation. I’d been apprehensive about installing the studs, worried about whether they’d truly line up properly and as intended with the factory pre-tapped holes in the ring I’d glassed beneath the foundation and how well the transmission bolting pattern truly lined up with the ring; I’d seen too many instances in the past where similar things designed to fit together in a specific way simply didn’t work out properly in the dynamics of the real world. But I was pleasantly surprised now that I could thread in all the studs without any problem once I’d aligned the transmission as needed.

There was only one minor snag in the studs’ installation: the starboard aftermost stud wouldn’t fit past the bolt securing the hinge mechanism at the aft end of the transmission. I suppose if this were being installed as suggested by the directions (but impossible in this specific case), where the studs were pre-installed in the foundation and the transmission dropped straight down over the top afterwards, this would not have posed a problem, but now I had to remove the nut from that bolt and push the bolt through till the end was almost flush with the housing before I could insert and thread in the stud.

After ensuring that the leg was where it was supposed to be, and that the gasket looked good from the opening beneath, I secured the transmission with washers and nuts over the studs. This also went swimmingly till the final two nuts, one on each side, where for whatever reason the nuts cross-threaded on the studs before reaching their termination. Fortunately, this happened at a point where I could still unwind the nut and stud without particular issue, and there happened to be two or three extra studs and nuts in the package, so this was a minor–if still irritating–setback.

I wasn’t sure whether the forward pair of studs (the studs were quite long and stuck up a couple inches from the transmission flange) would interfere with the engine during installation on the transmission, so I cut off the excess bolt length in these locations now, just to be sure.

I hooked up the engine to my overhead crane and lifted it up and into the boat, then down into the engine room. I spent some time jockeying the engine around and trying to align the transmission shaft with the corresponding socket on the engine’s aft end, but ultimately didn’t succeed: there were many variables, from the precise position of the notched shaft to the height and various angles involved between engine and transmission, all complicated by the fact that the chain hoist ended up pressing tightly against the companionway when I really needed some extra wiggle room, plus the fact that the socket on the engine housing was recessed and impossible to see to help guide in–or even determine how to move for better alignment–the transmission shaft. Obviously I would eventually prevail in this connection, but for now, at the end of the day, I parked the engine on a cushion forward of the engine room and left it to be dealt with next time.

Total time billed on this job today: 4.75 hours

0600 Weather Observation:

32°, clear. Forecast for the day: sun, 50