October 10, 2016

Acadia 14

Monday

After spending the morning on another project and other commitments, I turned back to the pedestal control cables’ removal. Hanging down into the lazarette from above, I was able to loosen the nuts securing the tensioning eyes on the steering quadrant, which slackened the steering cables enough to allow me to (still with difficulty) move the chain in the pedestal and, finally, pull out the engine cable clamp through the tight opening. Before pulling the cables, I secured messenger lines to their lower ends so I could feed the new cables in later.

Pleased with this success, I proceeded to pull the cables through–it was far more difficult to pull then than I’d expected, with a lot of friction–, and then both cables just hung up and wouldn’t move at all, causing momentary vexation, but the reason eventually became apparent: there was a secret second control cable clamp located near the bottom of the pedestal. This prevented me from pulling out the cables, and was not something I’d found any mention of in any of the Edson documentation covering control cable replacement. There was another nut securing this second clamp, and though the nut was reluctant to release from the aluminum pedestal, eventually I removed it, releasing the second clamp, at which time I could completely remove the two control cables.

The original cable clamps were aluminum, with stainless screws holding them together, and inevitably after 37 years, the screws were well corroded into place in the aluminum housings, and removal of the old clamps in a usable way seemed unlikely, though I’d soak them in penetrating solvent in an attempt to allow removal. I ordered a replacement clamp to have on hand either way–I saw no need for the second, lower, cable clamp, which seemed like it’d be virtually impossible to secure with the pedestal in place anyway.

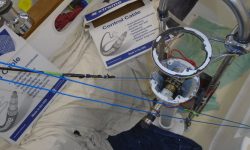

Meanwhile, I could at least start the new installation by feeding the pair of new cables I’d ordered earlier into the pedestal from above. With the messengers well-taped to the ends of each cable, one at a time I fed them down and, finally, out the lower end of the pedestal into the space beneath the cockpit, ensuring that each cable led directly from the base to the top without being twisted or otherwise interfering with the steering chain and cables, nor the compass wiring. I’d never have gotten the cables threaded down and through the bottom holes of the pedestal without the messenger lines. I could finish up the upper end of the cables, including the clamping, later on, when my new clamp arrived, but my immediate goal had been to continue to finish up those projects that were more easily done before the engine installation continued, while I’d as much space inside the boat as possible.

With what I hoped was the worst part of this nasty chore over with, I took a moment to apply a quick coat of 2-part epoxy primer to the new fiberglass in the aft end of the engine space–the strut and stern tube patches, and the waterlift platform–to prepare these newly-epoxied areas for engine room paint. I wanted to finish out the space beneath the fuel tank before the engine foundation was in place, as access was much better now, and one-part paints tend not to cure properly over new-ish epoxy without the tie coat between. I happened to have leftovers from a batch of the primer that I’d used on another project earlier in the day, so it was the perfect opportunity.

Total time billed on this job today: 2.5 hours

0600 Weather Observation:

45°, clear. Forecast for the day: sunny and windy, high 57°