January 3, 2019

Dharma Rose 23

Thursday

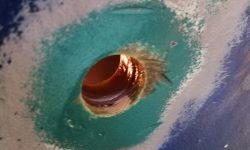

I spent most of the morning working on the galley sink through hull, which the owner had recently asked me to replace. The original fitting was the usual ball valve-on-a-stalk.

Access within the locker was tight, but I almost got the ball valve to unthread on its own, which I always try first: it jammed after half a turn, at which point I abandoned my attempt to remove the fittings this way and instead ground off the mushroom head from outside and removed the fitting easily from there. Afterwards, I sanded the hull outside and inside the locker to prepare the surfaces for new work.

From 3/4″ G-10 fiberglass, I prepared a backing pad to fit, and went through the various steps to prepare it and the flange base for installation, much as I’d done for the cockpit scupper through hulls earlier.

I dry-fit the pad in the boat, and glued in a support block beneath it to hold it while the epoxy adhesive cured. Then, I applied epoxy to the threads and heads of the bolts, tightening them down into the mash, and installed the backing pad in a bed of thickened epoxy, cleaning up all excess inside the hole and around the pad.

Meanwhile, I took a moment to install a zerk fitting on an existing through hull for the engine intake, which the owner had also requested. The 1/8-27 SS zerk fitting fit in the original drain plug hole. These fittings were a new and recent addition to this line of ball valves, designed to allow grease application and help keep the ball from sticking over time (a common issue when the fittings aren’t used regularly).

With new supplies on hand in the afternoon, I could finish up a few tasks, starting with the engine control cables. While access was still relatively good with the fuel fill hose out of the way, I made up the connections behind the control, switching the gear control cable to the opposite side from before, since this transmission required “pull” for forward. I left the cable ends in the engine compartment for now and would make the connections to the engine once it was installed.

Now I could finish up the fuel system with the fuel fill hose. Similar to the original installation, I used a heavy plastic hose barb-to-pipe elbow to allow the fill line to make the bend into the tank inlet. The original fitting had used a female threaded end with a threaded male hose barb, but I chose a male threaded end to eliminate an additional fitting and joint. To allow the hose to fit, I ground off the threads from the end. The way the fuel hose had to turn and connect to the tank obviated the possibility of using a hose barb elbow in this installation.

Up in no-mans land, out of sight and barely within reach, I secured the top end of the hose to the existing deck fitting with two clamps, and reconnected to the tank the existing ground wire.

With the remains of my battery cable, and newly-supplied lugs, I made up the pair of negative cables from the buss bar in the engine room to the battery compartment, completing the basic new wiring work for the electrical system.

Total time billed on this job today: 7.5 hours

0600 Weather Observation: 26°, light snow. Forecast for the day: Snow in the morning, 2-4″. Clearing later.