November 26, 2018

Dharma Rose 2

Monday

Dharma Rose’s owner brought her to me to accomplish several larger jobs that he deemed crucial to his future sailing plans, including replacing the original engine with a new Beta 14, installing a new Monitor self-steering windvane, and some semi-structural work in the cabin to repurpose a built-in keel-mounted waste tank, along with sundry maintenance and upgrade items along the way. The boat was in good original condition that generally belied her age.

The engine replacement was the #1 job on the list, so after removing a small amount of gear from the boat to clean out the cabin and storage areas, I removed the cockpit sole to gain access to the original Bukh 8HP diesel beneath. I was impressed by the appearance of the engine and engine room, both of which were cleaner than usual, and the engine itself (and related components) were so free from corrosion that I guessed the boat must have had the luxury of a mainly fresh-water life. Clearing the way for the work ahead, I immediately pulled out of the way a length of ventilation hose that ran through the space, pulling it aft into the lazarette for now.

I began outside to remove the propeller, which I like to do immediately since using a prop puller requires that the shaft be secured and there’s no better time to do it than at the onset of the engine removal. There was a prop zinc secured over the prop nuts, a two-piece design that clamped together between the two nuts, and while I suspected there were little screws holding it together, their heads were filled with corrosion or debris, so I simply knocked off the zinc after chiseling a groove through it, exposing the nuts for removal. I tied the rudder to one site to improve access, Neither nut was particularly tight, so they came off easily once the zinc was out of the way.

I used a small two-blade prop puller to remove the propeller next, which also went more easily than I’d anticipated: just setting the body of the puller behind (forward of) the prop hub was enough to loosen its grip on the shaft, and I pulled it off easily. The original propeller was two-bladed, size 12RH13. Afterwards, I made some measurements of the shaft clearance and aperture size for future reference in spec’ing new equipment later.

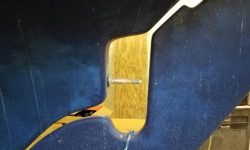

Now up in the boat, I began to disconnect the engine for removal. I tried to work systematically from aft to forward and top to bottom, removing anything that connected the engine to the boat. I started with the shaft coupling, which once more was pleasingly free from corrosion, and the four bolts released without a fight.

Next, I removed the exhaust hose from the elbow; since I planned to replace the hose, I cut it just below the nipple. I also removed the small vent line, which ran up into the port cockpit locker where there was a vented loop (I hoped to reuse these components). Meanwhile, still near the aft end of the engine, I removed the throttle and gear control cables and moved them out of the way. I disconnected the wiring harness leading to the engine panel down in the cabin, but found that the wires were pinched somewhere along their run, somewhere out of my immediate reach, so for now I left the panel and its wiring for later.

In this way, I moved my way along the engine, removing the four nuts securing the engine to the flexible engine mounts, fuel lines, electrical connections, and raw water hoses as needed till the engine was free all around. Knowing I needed to reduce the width of the engine in order to fit it through the opening directly above, I removed the air filter and exhaust elbow, and while I knew I’d probably have to take something else off later, I held off more disassembly for now since I wanted to minimize how much I did before knowing it was necessary.

With the engine free, I hooked up my hoist and prepared to lift it out. I soon found that anything that could get caught somewhere and hang up the engine definitely would get caught somewhere and hang up the engine, so it was with significant continued effort and various additional parts removals (including three of the four wide engine mounting flanges, the secondary fuel filter assembly, and more) that I finally somehow wedged the engine up through the tight opening and into clear air. It was obvious that this engine had been installed in the hull before the deck was installed above since the physical dimensions simply didn’t work any other way.

I lowered the engine to the shop floor and a little rolling dolly so I could move it around easily. Since the owner already had someone interested in buying the engine, I’d tried to be careful during its removal, and now I reassembled the various parts I’d removed in order to make it whole again.

Meanwhile, back in the engine room I bailed out the engine drip pan, which was full of water, and cleaned up the space a bit further, removing the fuel filter and pulling the fuel lines back into the fuel tank locker for the moment before calling it a day. I’d continue work in the space next time.

Total time billed on this job today: 8 hours

0600 Weather Observation: 34°, cloudy. Forecast for the day: Cloudy, showers to rain/snow/mix overnight