December 12, 2017

Jasmine 8

Tuesday

Before beginning the deck repair work, a few items remained for me to remove, starting with the mainmast chainplates. Access was fair to most of these locations, but in the head, where two of the port chainplates were located, the sewage system hoses and a shelf in the cabinet made access tight. I improved the access by removing the shelf, which was necessary for reasonable access to the aftermost chainplate bolts. As I went, I removed obsolete wiring bundles from the head locker, and also from the hanging locker on the starboard side. After a time, I successfully removed all the chainplates and put them aside for later assessment and possible refabrication.

I took a moment to cover the engine, which was partially disassembled, with a towel and some plastic sheeting to keep out debris and dust during the bulk of the deck project again. Afterwards, I spent a few minutes in the cockpit removing an access plate from the cockpit sole, along with a trim ring around the manual bilge pump and the cover plate over the engine controls–all to improve access for surface preparation, repairs (as needed), and eventual painting.

I went over the entire deck, sounding with a hammer and otherwise determining the condition of the decks and locating any areas requiring core repair. Several of these areas were readily apparent, namely both sidedecks in way of the chainplates and the poop deck, and I marked the rough location of these areas for future cutting. In other areas, I marked any isolated areas of suspect soundings–mainly small latent voids–and when I felt it was necessary I drilled 1/2″ holes into the core to determine its condition. I was happy and a little surprised to find that other than the large areas on the sidedecks and poop deck, most of the deck was sound as is, including the foredeck, coachroof, and cockpit areas. I marked off some marginal areas around one or two stanchion bases and the large hawsehole on the foredeck for possible core removal.

At the poop deck, I removed a wooden frame from around the steering gear hatch, which exposed the coring within (all of which was badly rotted) and would make cutting and repair more straightforward.

The coachroof in way of the main mast step seemed sound, other than localized damage around some old wiring holes. However, it appeared that the step had compressed the core material beneath, causing a slight depression, so I decided to remove the step and replace the core beneath with solid fiberglass. Because of some corrosion at the mast base itself, the owner wanted to cut off a few inches of the mast to remove the bad area, and this might also lead to rebuilding or replacing the step with a higher version to help make up for the height difference–all to be determined over the course of the project.

To remove the step, I chipped out some filler material surrounding the four lag screws (hex head), then easily removed the screws and the step itself.

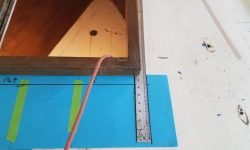

I made a simple template to help me properly relocate the step later, using the forward hatch frame as my reference guide.

In the cockpit, I removed the mizzen step just to clear the way for more effective surface preparation.

Now I was ready to get to work on taking apart the deck for repair, and I chose to begin at the poop deck. Here, the damaged area ran around the entire stern of the boat, from the winch islands on both sides and across the poop deck. Leaving an edge of the original deck in place, I used a saw to cut off the top skin, over half the stern at a time; the core was in such poor condition in post areas that the skin was easy to remove by hand once the cuts were complete. With the skin removed, exposing the black, rotted core, I scraped out the old core material from the flat areas, and dug out what I could for now from beneath the cut edges.

With the port half de-cored, I moved over to the starboard side and repeated the process. Here, the aftermost chainplate was still in place for the moment, awaiting eventual removal, but it was easy enough to work around for the moment. At the forward corner of the new opening, just aft of the winch island and in way of the aftermost stanchion base location, the core (and/or a mass of solid fiberglass) was more heavily fused to the inner skin than anything I’d ever run across, the apparent result of a previous spot repair to this area that had been visible on the top skin, and this caused some damage to the bottom skin that I’d have to repair before installing new core.

With the bulk of the core scraped out from around both sides, and beneath the flanges to the extent possible for now, I cleaned up and disposed of the detritus. I’d continue work on other areas of the deck next time.

Total time billed on this job today: 7.5 hours

0600 Weather Observation: 19°, light snow. Forecast for the day: A few inches of snow, then changing to rain and eventually warming to the 40s