February 9, 2018

Jasmine 48

Friday

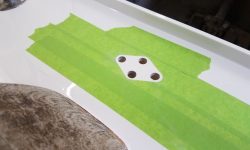

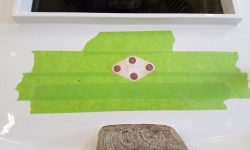

To replace the old 110V shore power plug, which hole I’d sealed over during the deck work, I ordered a new, modern plug and prepared now to install it. The original receptacle had been located perilously close to the steering room bulkhead hidden behind the cockpit, and this was one reason I’d chosen to fill the old hole. Back then, I’d noted some reference points so I could determine the new location after the paint was complete, and with this in mind I used the rubber gasket from the new receptacle to lay out the location for the 2-1/2″ hole required. I wanted the new hole to be outside a line even with the steering room hatch trim, so I used a steel ruler to extend this and position the hole accordingly.

With the hole cut, I installed the new receptacle with its included gasket and machine screws. There’d be no wiring to the plug for now, but the owner wanted it in place for future use.

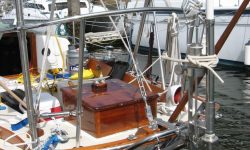

By now, I’d familiarized myself enough with the Norvane windvane mounting system to understand that none of its mounting components would impede the hardware placement on the poop deck. I’d avoided pre-preparing any of the deck locations or fastener holes for the stern hardware because at the time, I didn’t want to commit to any locations that could adversely affect the windvane.

The owner even sent me a photo of a similar installation on a sistership, which was greatly helpful in visualizing the entire arrangement, and this, along with my increasing knowledge of how the setup worked, allowed me finally to proceed with the hardware on the poop deck.

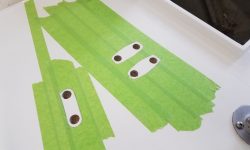

I laid out the stern mooring cleat positions, along with two new padeyes for the mizzen mast running backstays, plus a new padeye on centerline aft of the hatch for the mizzen sheet. The setup when the boat arrived had included a ridiculous tiny traveler for the mizzen sheet, which seemed not only poorly executed but also entirely unnecessary, so the owner agreed that a simple attachment point would make more sense.

In my habitual way, I cut away the masking tape around each piece of hardware, then marked and drilled out the top skin and core material in way of each fastener location. Then, I filled all the holes with a thickened epoxy mixture.

In the meantime, I worked to locate and prepare the holes for the cockpit sheet winches. These winches were new to the boat: they were some older model self-tailers (Barient 24) that I had on hand from another boat, and that fit the owner’s desires for winch upgrades. The winch replacement would also, thankfully, avoid the irritations and bolt layout I’d dealt with during removal of the original winches some weeks before.

I didn’t have the correct fasteners on hand to complete the winch installation, but got all the holes prepared and ordered the correct fasteners for next time. I also figured out any other gaps in my fastener inventory and ordered what I’d need to complete the Norvane installation, as well as the final hardware elsewhere on the boat.

Finally, I installed a length of piano hinge on the aft side of the steering room hatch. I wouldn’t do the final hatch installation till I’d completed all the work on the aft deck, since access within was much easier without the hatch.

Total time billed on this job today: 6 hours

0600 Weather Observation: -8°, clear. Forecast for the day: Sunny, mid-20s.