December 18, 2017

Jasmine 12

Monday

Working on an unrelated shop project over the weekend, I decided to take a few moments to disassemble the two side anchor rollers from the old bow platform, which would leave the wooden portion available for easy patterning; frankly, the platform was in my way. The old stainless steel rollers–one on each side–featured a 5/8″ thick threaded rod passing through the meat of the platform, secured with a nut on each end, along with wood screws to secure the roller frames to the side of the platform. The wood screws were easy enough to remove, but the large nuts seemed at first not to budge–but then simply shattered apart on each side under the wrench pressure. At that point, it was a matter of a little elbow grease to force the old roller assemblies off the shaft, then hammer out the shaft from the platform itself.

After double-checking the positions of the previously-marked cutout areas on all the core pieces, I removed the core and cut out these areas, the final step before core installation. After various other preparations, including gathering sandbags, plastic sheeting, and so forth, I got started on the core installation with the two smallest pieces on the foredeck. Here, and for all other areas to come, I began by wetting out the core on both sides, getting epoxy resin into the scrim and the kerfs between core blocks as much as possible. In the voids on deck, I wet out any exposed/adjacent coring, filled the empty space beneath the deck edge with a thickened epoxy mixture, and applied epoxy adhesive to the substrate with a notched trowel before pressing the core into place and applying weight to hold it while the epoxy cured.

Continuing, I repeated the process with the large area of the port sidedeck…

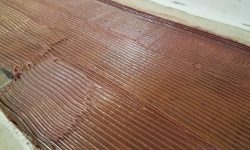

…and then the corresponding area on the starboard sidedeck. Here, during a quick break in the activity while changing gloves, I took advantage of the rare “clean” moment to snap a couple pictures of the deck and core after applying the notched adhesive and all other related preparations.

Moving aft, I similarly prepared and installed the new core in the narrow sidedecks outboard of the cockpit.

I would have liked to install the final core pieces on the poop deck , but didn’t have enough weight bags to continue. However, this gave me an opportunity to first install solid 3/8″ fiberglass strips, 1″ wide, around the perimeter of the steering room hatch opening. These would seal off the core around the opening, and provide strength and stiffness to the whole area as well. I glued these in place with more thickened epoxy, clamping them around the opening for the glue to cure.

Throughout the day, in a series of three separate installations to prevent excess heat buildup during curing, I installed about 13 layers of 1708 fabric set in epoxy resin in the main mast step area, bringing it close to flush with the adjacent deck.

Total time billed on this job today: 7.75 hours

0600 Weather Observation: 0°, mostly clear. Forecast for the day: Increasing clouds, light snow in the afternoon, 1-2″ forecast.