December 28, 2021

Lyra Phase 2-3

Tuesday

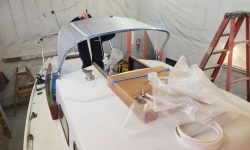

A week or two earlier, Jason, the canvas contractor, had come by to get some basic measurements of the boat in order to make a new frame. With the frame built, but with the legs intentionally a bit longer to allow for some final height adjustment on the boat (we’d not had all the information about boom and owner height during the initial consult), the first real step towards building the new dodger was to finalize the frame height and position. I happened to be the same height as the boatowner, which was handy for helping determine the final frame height, and along with some boom height measurements provided in the interim, it took two tries, removing a bit of the frame legs each time, to lower the frame appropriately and to its final height, after which we could install the bases on the coachroof and secure the frame in the correct position, with the main (aft) bow just a bit higher than the forward bow, and confirming the position visually and with measurements for symmetry, inasmuch as possible.

Next was to determine the landing point of the forward edge of the dodger, which defined the essential shape and appearance of the product. The angle of the forward edge was to approximate that of the forward end of the doghouse, which we eventually accomplished visually, and used this information to lay out and locate the first of the deck tracks required to form and secure the forward edge of the canvas: There’d eventually be three tracks, one each on the sidedecks (curved for appearance), and a third section on the sea hood. These plastic tracks could be manipulated with heat and curved to suit, and after a while we landed on the correct shape and position for the port track and secured it temporarily to the deck. Using this as a guide, Jason made a simple template, with some key reference points, to transfer a line for the curve to the port side, and repeated the installation process there. Then, mainly by eye, Jason located the third section of track on the sea hood; this also formed a slight curve to match that of the frame above.

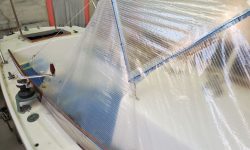

The final photo in this series attempts to show the eyeball view from the cockpit, just skimming the top of the dodger frame at my height. This view would be good for distance visibility; for closer views, one need only duck an inch or two down to look straight through the dodger itself.

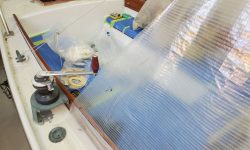

With the frame and all key attachment points in place, Jason moved on to the plastic pattern, beginning with the top, then the starboard side, and finally the port. With a 12″ long (vintage) winch handle that I keep on hand for these sorts of things, we made sure there was ample clearance to the dodger wings at the primary winches, and inside the dodger, there was ample clearance for a handle for the main halyard winch as well, at least for a 10″ or 8″ handle, which are common these days (the 12″ handle just interfered with the frame on the side). Note that the end of the plastic shown here forming the wings does not represent the final position of the canvas; instead, there are some tick marks on the plastic, visible particularly in the photos of the port side, that roughly signify for Jason the final, slightly-curved shape of the wing.

Afterwards, we removed everything, and the process would continue some weeks in the future once my main work list for the boat was complete, and she was reassembled.

Total time billed on this job today: 4 hours

0600 Weather Observation: Snow showers, dusting overnight, 24°. Forecast for the day: Snow showers, freezing drizzle, but improving, 36°