January 17, 2022

Lyra Phase 2-15

Monday

The satin varnish on the mast beams had cured nicely, and these were ready for reinstallation when the time was right.

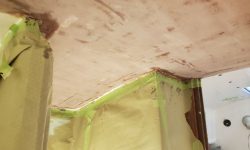

After the usual quick water-wash, I gave the new fiberglass on the inside of the coachroof repair area the lightest of sandings to prepare it for the next steps.

Belowdecks in the head, I sanded the overhead, otherwise known as the opposite side of this repair, where I’d installed a skim coat of fairing compound earlier. There’d be some hand-sanding around the edges, and some touch-up here and there, but otherwise this area was close to completion.

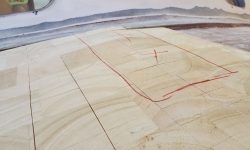

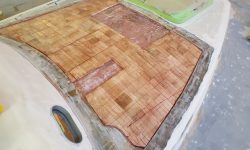

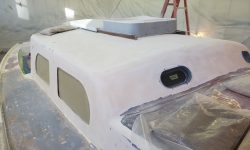

After cleanup, I laid out and cut 3/8″ balsa core for the large coachroof repair, and also the smaller repair aft. There was one bulge in the inner skin, an area I’d not been able to completely eliminate during earlier steps because of the overall nature of, and access to, the area in question, forcing the bulge to remain. I thought of just letting the core ride over the bulge, with the excess to be removed later, but it was too high and it would have been difficult to sand away the excess core from such an area, so I chose to cut out this small section above the high spot, and I’d fill it with solid fiberglass later.

I also omitted the core from a large area behind the hatch, in way of the mast step, which I would laminate with solid fiberglass in the end result for strength and, more importantly, compression resistance.

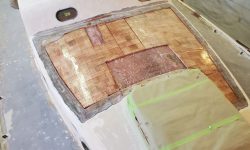

The newly-strengthened coachroof inner skin was much stiffer than it had been originally, and didn’t flex much under pressure, but to be sure I shored it up belowdecks with the plywood template I’d made (and ultimately never used during the inner skin repair) and a brace to the sole. I didn’t brace further as I didn’t expect the skin to flex at all further outboard.

After a final and thorough cleaning of both areas to be recored, and other preparations, I wet out with epoxy resin all the core pieces down on the bench then, beginning with the small area on the starboard aft coachroof, installed the core in epoxy adhesive. For this section, I began by filling the voids around the opening with thickened epoxy (high-density and cabosil), as I’d not yet done so, but for the larger repair, I’d previously done the edge work so it was a matter only of wetting out the substrate and installing the adhesive with a notched trowel before installing all the wet-out core pieces, pressing them into the adhesive and then, after covering the area with plastic, weighted down with sandbags.

Afterwards, I contented myself with finish-sanding the accessible deck areas, working through 80-120 grits on a 6″ orbital finishing sander over the wide areas, some hand-sanding at the toerails, chainplates, and other tighter areas, and additional machine sanding with a palm sander, mainly in the areas outside the reach of the larger tool. This brought the decks mainly to their final preparedness for primer, excepting of course the coachroof and its ongoing repair, along with various small areas still requiring some hand work or ongoing minor filling and repairs.

Total time billed on this job today: 6.5 hours

0600 Weather Observation: 22°, light snow. Forecast for the day: Snow, a few inches, then changing to rain and windy, 40°