February 14, 2023

Further 45

Tuesday

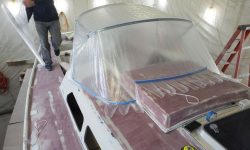

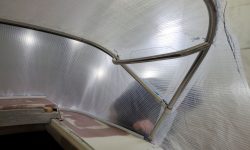

The second go-round of the dodger template got underway first thing. Armed with new track sections and renewed resolve, Jason set to work with the existing frame and top pattern (which had stayed on the boat in the meantime), and then worked to establish the all-important windshield angle that had proved elusive last time. The general goal was for the dodger shape to recall the angle at the forward edge of the cabin trunk, somewhere around 42°, so with the frame set up and a stiff batten, determining where that angle would land on the centerline created the first key point required to establish the rest of the parameters defining the front part of the dodger and installing the three track sections. For reference, the center track, mounted on the sea hood, had been installed roughly 6″ aft on center from where it ended up this time; there’s a blotch of (sanded) fairing compound visible at the center behind the track in the third photo below that is the filled hole from last week’s installation. So the new track locations were substantially further forward, which of course was what was necessary and expected this time.

With the tracks installed, the rest of hte templating process went quickly and successfully, and the new shape with its angular windshield (and resulting expansive “dashboard” on the inside) matched our expectations, the angle of the cabin trunk, and the overall shape and appearance of the boat to create the intended and desired result.

Once Jason left, I got back to masking for the remainder of the day, working my way along and masking ports and deadlights, various hardware, and the openings for the two cockpit locker hatches.

For this boat, I planned to do all the deck priming and painting first, then move on to the hull; normally I prefer to do the primers for hull and deck concurrently. But in this case, moving the staging back and forth would be too complicated and time-consuming, and didn’t make sense. So I had to establish a masking point between hull and deck

On the hull, the deck paint would eventually extend roughly to the line of the original seam in the hull-deck joint (now glassed over smoothly), and with no rubrail to be reinstalled on this project, this line needed to be clean and accurate. After some consideration, and concerns about 9 coats of paint (6 primers and 3 topcoats) creating a too-heavy line at the demarcation, I decided to start with a line about an inch further down the hull then where the topcoat line would ultimately be. This would give me some room to blend in the primers and, later, properly establish the final and accurate topcoat line where it needed to be.

To begin, using the molded knuckle shape prominently visible at the forward third of the boat (which had been the original deck-hull seam), I determined the position from a nearby molded shape in the toerail, and used a compass set to this distance to make a series of marks along the length. I’d originally set out to make a jig from the top of the toerail, but my first attempt from 1/4″ plywood proved too flimsy, and by this point I’d run through the considerations detailed above and decided to make the final line later anyway. So for now, the markings I made were accurate enough (and probably would be anyway). I ran a length of tape beneath my marks; this is shown below.

Next, I ran a second strip of tape just below that. Once I removed the top layer of tape, I had my priming line set 1″ below the final position of the paint seam. Sometime later, I’d protect the hull beneath this line to prevent overspray. Later in the process, once the primers were on the deck, I’d accurately mark the topcoat line back around the position of the forward knuckle, and aft from there.

More masking and related prep remained, but for now the day was done.

Total time billed on this job today: 7 hours

0600 Weather Observation: Overcast, dusting of snow overnight, 29°. Forecast for the day: Cloudy but becoming mostly sunny, 38°