January 24, 2023

Further 30

Tuesday

There was no sanding to start the day. Whaaaaaaat??? I hardly knew what do do with myself.

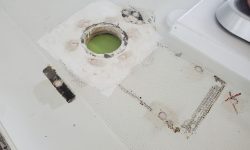

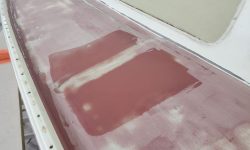

Oh OK, there was a little sanding: the coachroof core area required an easy sanding to prepare the inner skin and clean it up following the core removal.

With that done, I filled the void beneath the outboard edge with a thickened epoxy mixture, and skimmed more of the mixture over the inner skin to smooth and stabilize it, fill some minor tears from core removal, and begin to fill the large round hole at the aft end.

Next, I went around and filled all the fastener holes I’d bored out with the 5/8″ bit earlier, some of which would be re-used for reinstalling hardware, others of which were to be permanently filled and patched. I also partially filled, in a couple different “lifts”, the obsolete cowl hole on the port side, starting by filling the voids around the edges (where I’d dug out core earlier), then partially filling the large hole. Later, I planned to grind and patch this opening with fiberglass from above, but this was a start to the process.

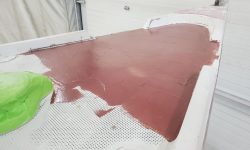

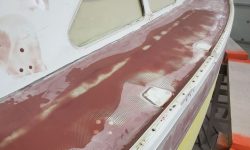

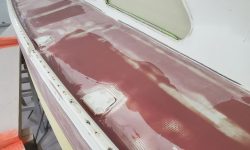

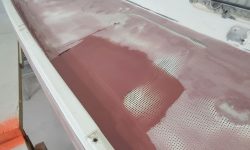

After cleaning up the sidedecks, I applied another round of fairing filler as needed, mainly on the areas outboard of the cockpit and foredeck, though I touched up several areas on the main decks, and also created an epoxy fillet to transition between the sidedecks and toerails on each side, in areas where the bulk fairing was otherwise complete. I troweled some of the fairing material into a series of small fastener holes in the cabin trunk that I’d previously prepared as well.

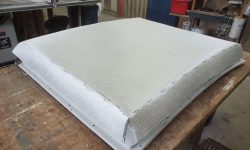

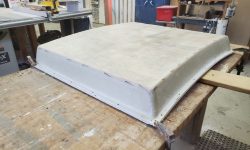

Next, I turned to the sea hood, and patterned a single layer of 1708 for the top skin to cover the core and complete the structure. Once I had the piece cut appropriately, I troweled on a skim layer of slightly-thickened epoxy to fill any open kerfs in the core, wet out the surface, and fine-tune the epoxy edges surrounding the core. Then I wet out and installed the fiberglass atop. The narrow edge at the sea hood opening refused to hold the fiberglass on its own, so I resorted to some clamps to keep it in place during curing. I intentionally left it long here for later trimming.

Total time billed on this job today: 6.5 hours

0600 Weather Observation: 19°, clear, 12" snow from yesterday, dew point 19°. Forecast for the day: Partly sunny, 37°