January 26, 2023

Further 32

Thursday

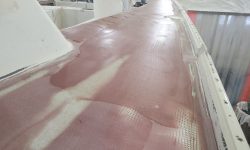

The next steps for the coachroof core repair, after removing the weights and a light sanding, began with a simple paper pattern of the area so I could cut the top layers of fiberglass. For the first two layers, which covered only the core and were necessary to bring the inner area flush with the surrounding flanges, I used the pattern I’d made for the core, and found I could use up some offcuts from earlier glasswork for these pieces. Once I’d cut the two layers, I wet out and installed them in epoxy resin atop the core.

Next, I cut two final layers to tie in with the adjacent decks, and installed them as well. I went right over the top of the large cowl vent opening at the forward end, as it would be easier to redrill the hole later than to try and cut material around it.

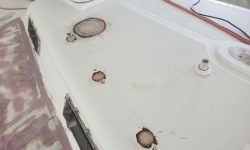

There were numerous small repairs to be dealt with on the coachroof, as well as in the cockpit and the through hull openings in the counter–places where I’d ground small dishes to accept fiberglass over permanently-unused fastener holes that I’d filled. To prepare, I marked and cut two different sizes of fiberglass patches, which shapes would fit all of the repairs needed. I cut some larger circles to fit the counter through hulls (both inside and outside), as well as some to fit the unused cowl vent opening on the port forward coachroof. For the through hull holes, as well as a couple larger openings on the small deck forward of the transom, I masked over the holes from one side and filled the holes with a thickened epoxy mixture first.

Next, I wet out all the little circles and other patches and applied them all over the boat where needed.

The foredeck repair, and the decks outboard of the cockpit, required additional fairing compound in places to begin to fine-tune the shaping, and I did this next, along with a second layer on the accessible screw holes on the sides of the coachroof here and there that I’d worked on earlier.

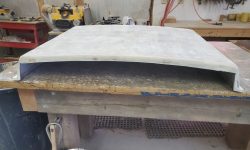

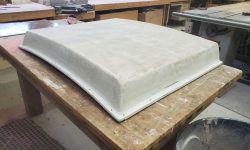

I had enough time left in the day to make progress on the sea hood, starting by cutting away the excess fiberglass from the aft (open) side where I’d let it run wild during installation, then lightly sanding the whole piece to prepare it for fairing compound.

Total time billed on this job today: 6.5 hours

0600 Weather Observation: 42°, rain on top of 4" snow overnight, dew point 32°. Forecast for the day: Rain before 10 AM, 40°