January 6, 2023

Further 19

Friday

I picked up where I left off on the starboard deck, starting with the large area I’d previously identified roughly amidships, near the chainplates. Since the damaged area extended near or through some of the chainplate slots, I noted some measurements of the slots for future reference.

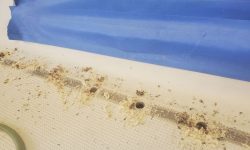

Then, I cut off the top skin along my lines I’d marked, exposing the core beneath. I immediately expanded the cutout at the outboard aft corner, as the wet core clearly extended further in that area, and found clean, well-adhered core almost immediately, which was good news. In other areas, my original cuts exposed sound core at the edges. Most of the rest was saturated mush, which I cleaned out now.

On the port side, when I brazenly cut out the entire slot in way of the inboard genoa track, I’d found there was much more sound core in there than I’d thought, as the damage was surprisingly confined near the fasteners, and removing sound, well-stuck core is a real chore that I preferred to forgo if possible. So on this side, I took a more piecemeal approach, though first I drilled out all the fastener holes with a 5/8″ Forstner bit, as before, which exposed some of the core and gave me insight into the conditions beneath.

Hoping that perhaps the core damage here was similarly confined, I turned to a 2″ hole saw to expand a couple of the holes as a test. This didn’t give me enough confidence, so from each end I began to incrementally remove a 3″ wide strip of top deck and core, which inevitably led to me opening the entire slot once more, but only because it was necessary and clearly obvious once I removed each section. Most of the core along the edges of the cutout was sound, though I reamed out portions and would return later for additional work, along with all the other areas currently exposed for rebuilding.

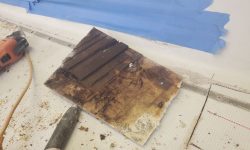

Just forward, at the chainplate area, there was a section of plywood core, which extended from the large chainplate against the cabin trunk. I’d removed most of this, but the portion still beneath the remaining deck flange at the cabin trunk was well-stuck, though completely dark and wet, and resisted efforts to remove. I tried various tools in my arsenal to little avail, and eventually drilled out the four bolt holes through the plywood to help loosen it and give me a chance. This helped, but there was still more to be done here. In the meantime, I reamed out the damaged core as needed from beneath the exposed flanges at the other edges of the opening, removing the bulk of the old material pending some additional detail work later to clean out the rest.

With my 5/8″ bit, I went around the boat and drilled out all the fastener holes left in the sidedecks and foredeck, including stanchion bases, cleats, chainplate fasteners, pulpit, and other hardware. Mostly, this revealed core in sound condition, which was good news, other than the midships stanchion base (P3) in the port side, which was already in an area currently opened for recore. The stanchion bases appeared to be plywood-cored beneath for added compression strength. Later on, I’d fill all these holes with a thickened epoxy mixture.

I’d now addressed all the most significant areas on the sidedecks requiring inspection and repair, so I finished up the day and the week by cleaning up a bit. With some messy work ahead in the immediate future–especially grinding and sanding–I took a moment to close off the deadlight openings to prevent as much dust as possible from getting inside the boat. At my suggestion, the owner had earlier masked over these openings from the outside, a down-and-dirty (or would that be clean) way to keep out dust during the early parts of the project. This had worked fine, but now the tape was coming apart a bit, and in any event I’d soon be sanding the cabin trunk in these areas, so I used paper and tape to cover the openings from inside, which would do the job required till much later in the project when it was time to start masking for paint.

Total time billed on this job today: 5.75 hours

0600 Weather Observation: 25°, overcast, dew point 24°. Forecast for the day: Patchy snow or freezing drizzle, then snow, 32°