January 17, 2023

Further 25

Tuesday

As per usual, I began my day with the sander, working on both sidedecks to sand the new laminate and clean up the edges along the adjacent decks as needed. I also sanded the nearby nonskid areas, starting at the aft end of the foredeck, to reduce the molded nonskid texture and prepare the decks for additional work and fairing in the repairs. The molded nonskid pattern was heavy and deep, and sanding it completely smooth would have removed far too much material and taken eons, so I sanded it heavily to remove most of the texture, but stopped well short of the decks being completely smooth. I’d skim-coat and fill the remainder to achieve a reasonable balance.

The skidmark-looking things on the deck are just that–skid marks from the bottom of my vacuum, which feet had worn through the cloth I maintain over the bottom to avoid damage.

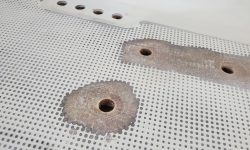

At the same time, I prepared a few areas for additional repair work, using a grinder to remove material around a pair of deck fill openings on the port deck, and to prepare the forward part of the obsolete port track fasteners for a strip of fiberglass over the top. I also lightly sanded the one layer of fiberglass on the bow repair that I’d started last time.

Next, I made preparations to fill most of the fastener holes in the sidedecks. I’d already opened up most holes with a 5/8″ Forstener bit, removing the core within, but now I went around and drilled out a few holes I’d missed before, and used a large countersink to ream the tops of the holes a bit to increase bearing surface for the filler. Inside the boat, as needed I masked over some of the holes to prevent any epoxy from dripping through into the cabin or lockers. After final preparations, I went around the sidedecks and filled all these holes with a mix of epoxy and high-density filler, leaving this to cure over lunchtime.

With the epoxy gelled sufficiently, I installed fiberglass patches over the deck fill openings, and one layer of fiberglass over the jib track holes (and a nearby test hole). Then I patterned and cut and installed two layers of fiberglass on the foredeck repair.

During the sanding session in the morning, I’d fine-tuned the cuts at the small sections of toerail on either side of the cockpit, where the original winch islands had tied in, cleaning up the cut lines at the top edges and bringing them back enough to accept a layer or two of fiberglass later, which would bring them back to the necessary width to match the other areas. The open area within was quite shallow and also uneven, with tabbing (now exposed on one side) pressed into the space in uneven ways. Over the past weeks I’d been considering how to proceed with these repairs, and now I filled the shallow voids flush with a thickened epoxy mixture, troweling it smooth to the top edge and a line I struck at deck level, which lines I’d masked to to ensure a clean line when all was said and done.

My plan was to bring the first layer or two of fiberglass up and into this now-flush space to tie the toerails back in and return the inside edges to their more-or-less final shape (fairing notwithstanding). I expected to require two layers of material over the core, to bring up the height properly, before installing a final two over the whole area plus the adjacent deck edges, but that was for a time in the immediate future, just not now.

Finally, I applied a coat of epoxy fairing filler over both sidedecks, including the adjacent nonskid and all repaired areas, to begin to smooth and tie these areas all together. I stopped a bit short of the aft ends to allow room to tie in the material outboard of the cockpit later. This skim coat mainly filled the existing nonskid and new repair laminate, as well as began to incorporate the molded deck edges (the nonskid pattern stood proud of the molded borders), but the overall profile on both sides was largely fair in an overall sense, with no significant hollows to fill. The epoxy in the fastener holes, and even the fiberglassed repairs on the port side, had gelled enough by this time that I could fair right over the top as needed.

Total time billed on this job today: 7.25 hours

0600 Weather Observation: 21°, overcast, dew point 24°. Forecast for the day: Sunny, 37°