January 20, 2023

Further 28

Friday

The day’s sanding duty began with the decks outboard of the cockpit, which I sanded as needed to ease and begin to fair in the edges with the surrounding decks, and to generally scuff the surfaces to prepare for continuing work. At the toerail repairs, where I’d let the fiberglass run a bit wild at the top and sides, I first trimmed the excess material more or less flush, before hand-sanding the narrow top edge.

After cleaning up, I applied a first round of epoxy fairing filler to these decks and the inboard sides of the molded cockpit coamings.

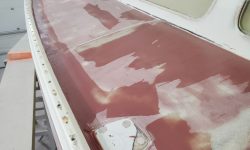

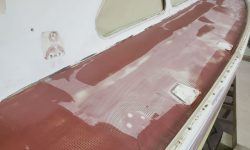

I applied more fairing filler to portions of the sidedecks, focusing mainly on the inboard and outboard edges of these decks as faired in the raised molded nonskid with the lower borders all around.

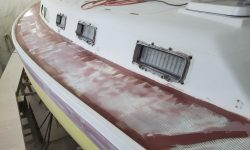

The original molded sea hood from the companionway featured three prominent external ribs, which stiffened the part. However, the shape and position of these elements would interfere with the ideal design of a new dodger, and during an earlier meeting the owners, canvas contractor, and I agreed that it would be best to remove the protrusions and rebuild the seahood flush on top.

The ribs were molded and hollow from the underside, and removing them would leave long slots in the top of the sea hood, as well as eliminate any stiffness in the part. To provide the requisite stiffness, I planned to add core material and fiberglass over the top, which would raise its profile slightly, but ultimately provide the desired appearance and compliance with the dodger plans. Before cutting away the ribs, I sanded away the paint from the underside and glued in some temporary strips of wood to help hold the piece in its proper shape. Then, I cut away the three ribs, ground the openings smooth, and heavy-sanded the entire gelcoated top. I didn’t see a reason to remove all the gelcoat.

To support the shape of the top while installing core, I built a simple support jig on the bench, with vertical members beneath each of the four sections of the top, and hot-glued it to the sea hood to eliminate any potential movement. I added shims at the four outboard corners to ensure the hood would remain steady.

I cut pieces of 3/8″ balsa core to fit the top, leaving space around the edges that I’d later fill with solid material, then wet out the core with epoxy and installed it in a bed of thickened epoxy adhesive, securing it with weights as needed and leaving it to cure overnight. Later, I’d fill the slots in the underside, and glass over the new core and onto the sides of the existing molding to complete the work.

Total time billed on this job today: 5.75 hours

0600 Weather Observation: 30°, snow, 3-4" down so far, dew point 26°. Forecast for the day: Snow, 5-9", 31°