January 9, 2023

Further 20

Monday

Before continuing work on the sidedecks, I inspected the coachroof all over, sounding with a steel hammer to locate any questionable areas that might require attention as well. Most sections seemed to be sound, fortunately, but I did find an extended area with evidence of damaged core leading aft from a Dorade vent opening on the starboard side. I sketched out the rough outline of the damage on the deck for later attention. I wouldn’t start work on the coachroof till the sidedecks were repaired to the extent that I could work on deck without tiptoeing between the open sidedeck areas, but I wanted to order replacement core and needed an idea how much additional I might need for the coachroof.

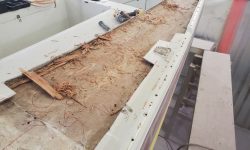

Next, I worked on cleaning up the deck areas already open for repair, focusing on removing the final bits of plywood from the areas beneath the winch islands, and cleaning out the deck flanges around the openings to get rid of the last bits of old core and prepare these areas for new work. Cleaning up the broader field areas of each repair would come later when I got into bulk sanding and in conjunction with some minor repairs needed to sections of the inner deck skin, mainly to cover unwanted holes and, in a few areas, to repair some inner skin damaged during the core removal. I used various chisels and reamers to rid the hidden edges of excess core, and used a wire wheel attachment on a drill to take care of the rest in the narrow slots.

Afterwards, I thoroughly cleaned out the slots as needed, with brushes and compressed air, and solvent-washed with acetone. On the port side, where one of the repairs surrounded a chainplate slot, I cut a piece of plastic to fit the slot and keep it open while I epoxied around it.

During the rest of the day, I mixed many batches of thickened, strengthened epoxy and installed it beneath the deck edges all around, forcing the mix all the way to the depths of all the openings. At three of the exposed stanchion locations, I added 1/2″ prefab fiberglass blocks beneath the bases to strengthen the installations and later accept the fasteners; only the midships base on the starboard side remained partially visible after installation, as the two after locations (outboard of the cockpit) were buried deeper and surrounded with more of the thickened epoxy. I chose to fill these edges at this early stage and before grinding the adjacent deck areas to prepare for new fiberglass because I’d often found that the flanges, if ground first, tend to “curl up” at their inboard edges as the thinned material loses its overall integrity, and this can complicate core and laminate installation later. In any event, this bulk sanding event was next on the agenda once the epoxy cured, the final prep required before new core installation.

Total time billed on this job today: 7 hours

0600 Weather Observation: 14°, partly clear, dew point 14°. Forecast for the day: Mostly cloudy, then gradually becoming sunny, 37°