December 21, 2022

Further 8

Wednesday

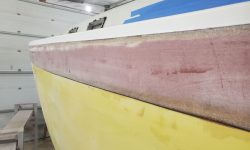

Another round of sanding brought the hull-deck joint to a point of readiness for the next step: fiberglassing. Since the immediate goal was an appropriately-flat, generally fair surface, but not a final finish, the few minor low spots leftover from trowel marks were either nothing to worry about, or something I could (and later would) fill with a skim of thickened epoxy before applying the tabbing.

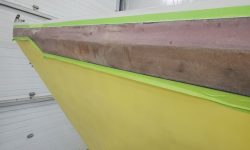

After cleaning, I applied tape to both sides of the area in question, using wider tape at the base to allow room to make a sort of drip edge to help avoid any resin runs down the topsides. A few minutes with the tape saves much potential labor in removing hardened bits of epoxy from adjacent areas.

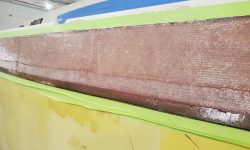

Starting on the starboard side, with a batch of thickened epoxy–just epoxy and silica–I skimmed the prepared area with a squeegee to fill some of the remaining lows, and also to wet out the entire area in advance. Afterwards, I applied two layers of 1708 tabbing–6″ and 4″–over the hull deck joint, keeping the layers aligned at their top edge, butting the adjacent pieces and staggering the joints between layers by half, like subway tiles.

I repeated the process on the port side. Near the port bow, where a flared copper tube/tank vent protruded, I protected the open tube with a small square of tape, then glassed right over it; this would be easy enough to cut out and remove once the fiberglass was cured. I also glassed over the hole on the port quarter near the transom for another tank vent, but this could be redrilled later.

These processes consumed the day. I removed all the masking tape from each side once the resin had gelled to the point where runs were no longer an issue; the few runs that occurred happened mainly at butt joints between pieces of tabbing.

Total time billed on this job today: 7.25 hours

0600 Weather Observation: 29°, overcast, dew point 22°. Forecast for the day: Gradual clearing, 35°