Thursday

I had a short day in the shop since I needed the morning to pick up one of the winter’s upcoming boats, but upon my return I got back to work on the winch islands.

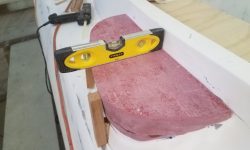

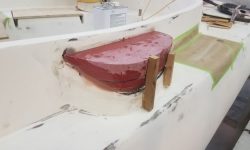

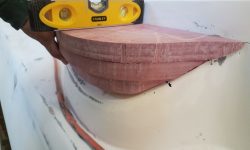

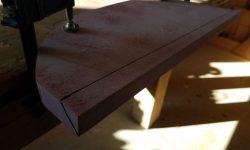

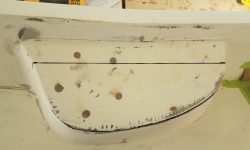

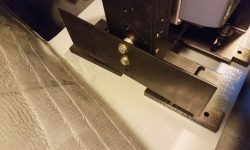

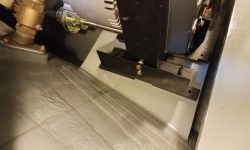

The additions created a sort of wasp-waisted appearance at the moment, but the top edge was in line with the base of the original island, so once the construction and fairing work was complete, the islands would be essentially straight and more or less plumb (whatever plumb might be on a dynamic object like a sailboat). The size of the top surface was dictated by the size of the winch base, and continuing the slightly-angled line of the original molded bases would have resulted in a top substantially too small.

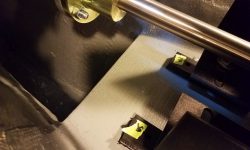

After a light sanding to smooth the first round of epoxy filler, and ease the top edge of the platform, I took advantage of the clean, dry surface to cut some fiberglass (not shown) that I’d eventually wrap around the outside of the assembly to tie the whole thing together and help provide a consistent surface.

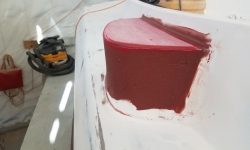

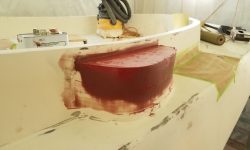

I applied another layer of fairing compound to the outer portion of the islands, using a broad trowel to bring the surface closer to its final shape.

I had hoped to use some of the work lamps I use for illumination to speed up the curing of this layer of compound so I could apply the fiberglass before the end of the day, but alas, I’d long ago switched to CFL bulbs everywhere and had no normal incandescent or specific heat bulbs on hand, and the cool-running CFLs couldn’t generate enough heat to be helpful, so I resigned myself to waiting till the ‘morrow once the epoxy was cured.

In the meantime, I continued work on the deck prep, focusing mainly on the forward hatch, which was a bit more complicated to mask off than I’d expected. Normally, I’d have awaited installation till after finish paint, but the schedule of the project and interior progress requirements dictated that I install it during the last phase of work. To effectively and safely mask off the hatch, I had to first mask off the flange and hinge area while the hatch was open, and then mask the remainder once I’d closed the hatch. The only remaining areas to be masked were the cockpit hatches and companionway, but I was holding off on those till the work on the winch islands was complete, lest I damage the new masking in the process or should I decide I just had to get into the cabin for something.

Throughout the afternoon, I finalized the order for the plastic fake-wood material that the owner requested for the exterior trim work (toerails, coaming caps, winch islands, and handrails). After various communications and final details the order was paid for and should be on its way for next week.

Total time billed on this job today: 3.5 hours

0600 Weather Observation: 33°, clear. Forecast for the day: Sunny, 61°