Scupper: Investigating rack and pinion aft-mounted steering option

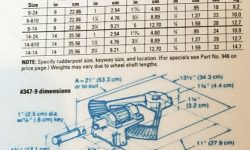

To begin the discussion of the rack and pinion steering option, I built a basic cardboard template according to the measured drawing from Edson. The correct size for your boat would be size 9-24, forward-mounting, which has a 1″ pilot bore for the rudder stock. This is custom-milled to match the specifics of each rudder stock, and your rudder stock is 1-1/4″. There is not room to install an aft-mounting rack and pinion without a major reconfiguration of the whole aft end of the cockpit and stern deck, so by requirement the rack and pinion assembly has to extend forward into valuable cockpit space.

The first issue at hand is that the bore, which is how the whole system is secured to and operates the rudder stock, requires a minimum height of 3″ (the thickness of the bronze casting itself at 1-3/4″, plus the height of the bore above the base of the unit which provides clearance for the rack operation, which is another 1-1/4″). Your rudder stock protrudes only 2-1/2″ above the deck, even without considering whatever sort of base/platform would be required to secure the rack assembly. The rack can’t be dropped below the level of the cockpit seats since the seats themselves would prohibit turning of the rack during normal operation. The rudderpost height cannot be extended without starting fresh with a new rudder and post to accommodate the extra length. Any enclosure also has to accommodate the rack as it turns from side to side.

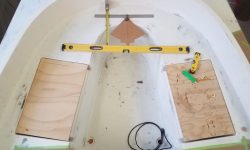

The following photos show the basic arrangement from various angles to try and show how this installation might impact the cockpit. The measured drawing shows a length of 21″ from the rudder post to the inside edge of the steering wheel hub, but I don’t think it has to be this long (if in fact 21″ is a required minimum, then the wheel ends up well into the cockpit lockers). The rack and pinion assembly is 11″ from the center of the rudder shaft to the forward edge of the mounting bracket (the square area at the forward end, and assuming the wheel can be mounted fairly close to this, including the thickness of whatever housing, for our purposes it’s safe to assume the steering wheel would, at a minimum, extend as far as the front edge of the yellow level in these photos. So this gives you an idea where the wheel would be in terms of the overall cockpit arrangement. I’ve included many photos trying to show this from all angles.

The shape at the aft end of the cockpit doesn’t lend itself well to a box enclosing the steering mechanism, nor for much room around the wheel at the forward end (the edge of the yellow level). The box enclosure would have to accommodate the rack at its far extent of movement on each side of the rudder (approximately 40 degrees each side), so the two photos below show what would be the minimal size of the box on each side, demarked by the steel rule. You can see how there’s no room to move around a wheel once a box is built in place, which seems to greatly limit utility of the steering system and doesn’t give the operator many options.

Construction of a steering box, which would enclose the mechanism and provide a helm seat just aft of the wheel, raises some questions as well, not only for the minimal room that would be available around it (unlike boats with a rectangular cockpit where the aft end provides a wider space), in terms of type of construction to go along with the low-maintenance, no-exterior wood mantra for this project. The box construction would be fairly involved and, from the initial looks of things, would be a sort of awkward and tacked-on addition to the cockpit, as well as not ending up very comfortable or functional, nor would it ultimately save room in the cockpit, since its design would force the helmsman forward of the wheel much of the time, as there won’t be usable room aft of the wheel given the curvature of the cockpit and the minimum width required to enclose the steering mechanism. The box would of course be a permanent installation that would limit space and flexibility in the cockpit seating both under sail and at rest. This also raises questions about where the electric motor controls should be located, and how this location might impact other occupants of the cockpit as well as utility by the helmsman.

My opinion is that this installation is not impossible (it certainly raised many issues), but that it is undesirable in the final analysis and ultimately doesn’t solve the space issues of a tiller in a satisfactory way. Construction costs would be fairly high, and would negatively impact progress on the remaining parts of the project and overall schedule. The Edson equipment is expensive on its own, and that’s assuming that the assembly could even be used given the less-than-required height of the exposed rudder stock; cost might be set aside as a concern if the setup did a good job opening up the cockpit during sailing and otherwise, but it appears to be even more intrusive than a tiller would be, never mind that the tiller can be lifted whenever not in use to clear the entire cockpit. Cockpit cushions are already built to accommodate the previously-specified tiller, and while these could be rebuilt or modified, it’s one more cost and complication to consider.

Posted Tuesday, October 22, 2019