< Back to Aventura

Monday

After a light water wash, as per usual, I sanded the various patches on the keel as needed, and cleaned up to prepare for additional work and fairing filler as required.

With a finishing sander, I lightly sanded the newly-filled gouges in the topsides. The smallest areas were fine after this round, but a few of the deeper areas would require additional fairing filler, which I applied now using a fine, smooth gray epoxy filler.

Next, I applied additional fairing compound as needed to the keel areas on both sides, concentrating on getting the overall shape and contours right rather than worrying about every ridge or minor void.

To get ready for the deck work ahead, I set up staging around the boat at deck height.

While working on and around the boat during the past week, I’d already determined several deck areas that would require core repair, but now I went over the deck carefully, sounding all areas and marking those where there was clearly an issue beneath. Most of the deck was sound, but these areas in the cockpit and foredeck would require repair.

During this inspection, I also determined that the port cockpit locker gutter system was coming loose from the deck; I’d noticed evidence of this from inside the boat when I was sanding the interior earlier, but from outside the issue became even more clear.

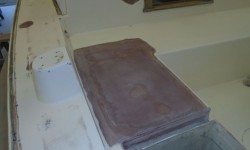

Starting with the foredeck, I cut open the deck to expose the core within the area I’d marked, the boundaries of which I’d left well outside the known bad area to ensure that the cut would extend into sound core. Then, I chiseled out the old core and dug it out from beneath the outer edge, where the core ended.

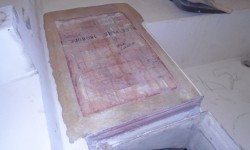

I continued the process with the area beneath the mast step. Someone had previously opened a small area of the deck here and installed a greenish polyester filler beneath the step itself, apparently in response to the sort of deck compression one might expect when locating a mast step on a cored structure. I removed this material as well for a fresh start: I planned to reinforce this area with solid fiberglass to better accept the compression loads of the mast and rigging.

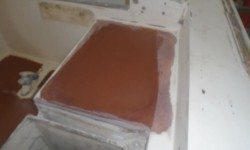

In the cockpit, there were three areas: the port cockpit seat (ahead and behind the locker opening), and the cockpit sole around the rudder post. Even before beginning, I could tell the seating areas were badly deteriorated, and when I made the saw cuts I was able to completely release the top skin and some of the core just by banging the skin like Fonzi at the jukebox. This made core removal in these areas a snap. Around the locker opening, I found that the builder had left exposed core at all edges, and that it communicated directly with the seating areas; this is clearly how these seating areas became wet and damaged in the first place, and I’d reconfigure the construction to prohibit this (and make the whole area stronger) as I went forward.

I made the cockpit sole cut well ahead of the known bad areas, and well into sound core material. As with all other areas, I strove to ream out most of the old core beneath the outer edges, as needed, but would come back during a later stage to continue that process.

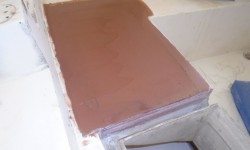

With all the core removed, I used a grinder to sand away the gelcoat and create tapered bonding surfaces all the way around all of the areas in question. At the same time, I ground out a few other areas on deck that would require patching or additional work, including the old water tank fill location, the old electronics holes in the cockpit bulkhead, and all the stanchion base locations, which, being located on thin, solid fiberglass outboard of the stiffer cored areas of the deck, had caused various stress cracking that required minor repair.

With the bulk grinding complete, I sanded the inner skin surfaces of all the uncored areas to remove vestiges of the old core and prepare the surfaces for later steps.

Total Time Billed on This Job Today: 7 Hours

0600 Weather Report:

Mostly clear, light fog, 32. Forecast for the day: Partly sunny, light wind, around 60.